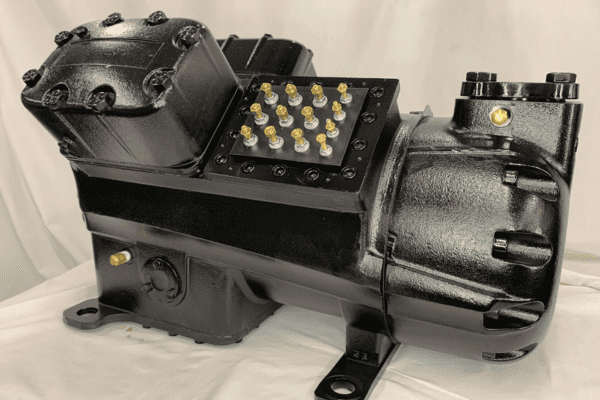

A remanufactured commercial compressor represents an excellent opportunity to achieve performance without paying a premium price. When you choose a true remanufactured compressor, you can rest assured that you’re getting equipment comparable to an all-new OEM unit, but doing it faster and more affordably.

When a commercial compressor is remanufactured, it goes through multiple important steps:

- It is completely disassembled so that the internal components can be assessed

- Components are replaced as necessary to deliver the unit’s full expected output

- It is cleaned inside and out to eliminate any effects of corrosion and pollutants

- It is always tested to ensure proper operation

In any situation where you need a commercial compressor, a remanufactured commercial compressor may be able to do even better. Not only can you expect to pay substantially less – saving 10%, 20%, 30%, or more depending on what you need – but you can procure your compressor weeks sooner.

Here are some situations where it’s wise to invest in a remanufactured compressor:

1. Your Existing Compressor Is 7-10 Years Old

With good maintenance, you can expect a modern commercial compressor to last anywhere from seven to ten years or more. Some brands are much better at maintaining their efficiency later in life than others, like Copeland and Trane, but you should have a replacement plan in place around that eight-year mark.

It’s unusual for a well-maintained compressor in the right operating environment to fail suddenly before its time. As you reach year eight, however, be aware that the day could come without any warning. It’s always best to have a remanufactured compressor on hand rather than have to source just anything in an emergency.

2. Your Existing Compressor Demands More Maintenance

Like any mechanical system, a compressor faces increased maintenance demands as it ages. Just like an old car, there comes a point where it is no longer cost-effective to keep pouring money into it. If you find yourself with a sharp uptick in repair bills, it could mean that the compressor is headed to an early grave.

Bear in mind that if you are spending a lot on maintenance and repair work, there may be a problem elsewhere in your system or in your building that needs to be addressed. Issues with an electrical voltage can be caused by an aging wiring system, to give just one scenario, and this problem will continue to damage a new compressor.

3. Your Current Compressor Has Failed Before

It is sometimes possible to bring a compressor back to life by performing field replacement of key components. But once a unit has failed once, it is usually only a matter of time before it fails again. Don’t be misled by the desire to improve your ROI by keeping a damaged unit running: An unexpected shutdown is too costly.

If your current compressor has failed in the past, be sure you know what the root causes were and have addressed them. It is especially important to be proactive about maintenance in this situation. That includes monitoring the surrounding area for pollutants, moisture, and other factors that can strain the system.

4. You Are Putting Higher Demands on Your Compressor

Every commercial compressor has specific output parameters and tolerance ranges it must stay within. Most modern compressors are designed so they can grow a bit with your needs, including when your cooling or refrigeration system must work harder than before. But any unit offers only so much “stretch.”

When you know that your system needs to ramp up, start planning your equipment acquisitions with that in mind. You will get much better performance out of a slightly larger compressor with the greater electrical draw than you will from a smaller, but older compressor that is being pushed near the limit of its tolerances.

5. You Have Extra Money in Your Equipment Budget

There are plenty of tired old arguments for waiting as long as possible before you make those key equipment buys. In the case of a remanufactured commercial compressor, though, the argument is reversed: You don’t have to wait for a bargain, so you will save more money by buying sooner and being ready for the unexpected.

If you have the room in your budget, having a replacement commercial compressor on hand will give you peace of mind. You can sleep easy knowing that not only are you prepared when a current compressor blows out, but you are also avoiding the hassle of weeks’ delays and huge price tags from an OEM-affiliated wholesaler.

If a compressor is the backbone of your business, don’t leave anything up to chance. Compressor failure can have lasting consequences for your operations within just a few hours. With a remanufactured commercial compressor, you are able to bounce back fast and keep going strong.