When it comes to commercial compressor technology, few brands can be called legendary. But as the originator of the modern air conditioning system, Carrier is one of them. More than a century has passed since that breakthrough, Carrier has become synonymous with excellence in refrigeration and HVAC systems.

At the heart of Carrier’s success, it has proven its capability to innovate and push compressor technology to new levels of performance while maintaining efficiency. Energy efficiency has become crucial over the last 20 years especially, and Carrier has not shied away from the challenge of doing more with less.

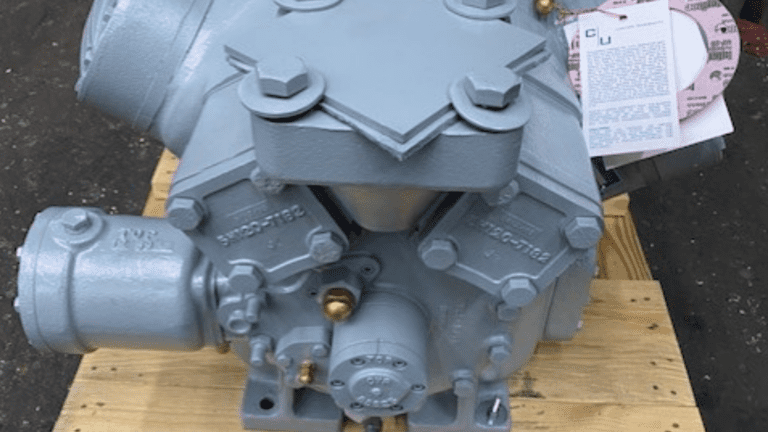

Of all its models, the Carrier 5H commercial compressor stands out for power plus eco-friendly engineering.

Why the Carrier 5H Is One of the Most Sought-After Models for Commercial HVAC Compressor Replacement

The 5H is an open-drive reciprocating compressor that comes in a range of 25 to 150 nominal horsepower and 92.4 to 346 nominal CFM. It features a wide variety of sophisticated engineering improvements that have made it a go-to technology for the most demanding work environments, including marine and off-shore.

But don’t overlook the rugged 5H if you are in a standard office complex or an industrial site.

With operable in belt- and direct-drive modes, every Carrier 5H is compatible with a complete selection of modern refrigerants including R-134a, R-404A, and R-407C. No matter whether you choose the 5H60, 5H80, 5H120, or another model, it’ll be easy to keep your system supplied with the refrigerant it needs.

That’s just one of the ways the Carrier 5H commercial compressor is easy to work with.

Let’s take a closer look at some of the innovations that make it one of the top compressors on the market:

1. Low Deployment Cost

With automatic unloaded starting, there’s no need to rely on an expensive high torque motor. Both the Carrier 5H commercial compressor and the 5F model can benefit from a specialized high efficiency motor that lowers startup expense and keeps the cost of ownership manageable.

2. Smooth, Unrestricted Refrigerant Flow

Keep your refrigerant supplies lasting longer with unparalleled passive protection against some of the biggest risk factors for commercial compressor failure. Refrigerant flooding and slugging are virtually unknown with a well-maintained Carrier 5H compressor thanks to updated crankcase casings, cylinder heads, and valve plates.

3. Virtually No Seal Leakage Even at Extreme Operating Temperatures

Compressor seal leakage is notorious for being one of the hardest compressor problems to diagnose. It is one of the top symptoms of “Old Compressor Syndrome,” that march toward lower efficiency as a compressor starts to age out. The risk increases around seven years in service, but it can and does happen even earlier.

Shaft seal leaks are slower leaks that can decimate your refrigerant levels over the course of a season.

Carrier has the solution, and they’ve implemented it throughout their 5H commercial compressor line: An all-new two-piece shaft assembly that supports high quality performance at a broader range of operating temperatures. It’s convenient, trustworthy, and a big money-saving feature.

4. Superior Protection for Your Liquid Refrigerant and Oil Supply

An effective crankcase heater is essential to maintain refrigerant at the correct temperatures for optimal output. Carrier’s cutting edge crankcase heater system is one of the most reliable around. It safeguards against accumulation of liquid refrigerant in the crankcase as the system is shut down and mitigates oil dilution.

5. Significant Savings Through Partial Load Operation

One of the biggest changes from previous models comes in how the Carrier 5H handles part-load operation.

An automatic capacity control system is linked to changes in suction pressure as the compressor operates. It can adjust to as little as 35% of the full-design load in a matter of seconds, reducing horsepower concomitantly. In some workplaces, that can amount to thousands of dollars in savings through lower electricity use.

What’s more, compressor operation at a reduced RPM supports greater efficiencies system-wide.

6. Exceptional Longevity through Positive Pressure Lubrication

The Carrier 5H delivers a combination of features that help the compressor maintain high efficiency as it ages, making it better in the last half of its lifespan than virtually any comparable compressor from the competition. Positive pressure lubrication is the last piece of the puzzle, further curbing friction and mechanical wear.

With a sophisticated system including a manually reversible oil pump, automatic pressure regulator, and state of the art oil filtration, lubrication failures are much less likely. This further contributes to low cylinder wear in combination with advanced cylinder sleeve cooling that uses the system’s own suction gasses.

A remanufactured commercial compressor provides everything you expect from a new Carrier 5H for less – and often reaches you weeks sooner. Just remember, a Carrier 5H must be sold with an exchange core. Be sure your remanufacturing team can help you meet this requirement!