When it comes to maintaining commercial HVAC/R systems, the reliability of your York commercial HVAC/R compressor is paramount. However, when a compressor fails, the decision between replacing it with a new one or opting for a remanufactured unit can significantly impact your budget and downtime. Remanufacturing a York commercial compressor offers a cost-effective and efficient alternative, but it’s crucial to understand the process and benefits to ensure you’re making the right choice for your commercial HVAC/R system.

Understanding Remanufacturing vs. Rebuilding

First, it’s important to distinguish between remanufacturing and rebuilding. Rebuilding often involves replacing or repairing only the components that are visibly worn out, which can leave other parts still prone to failure. This approach might save time and money upfront, but it often results in a compressor that doesn’t meet the original performance specifications, is not covered by any warranty, and is likely to fail prematurely.

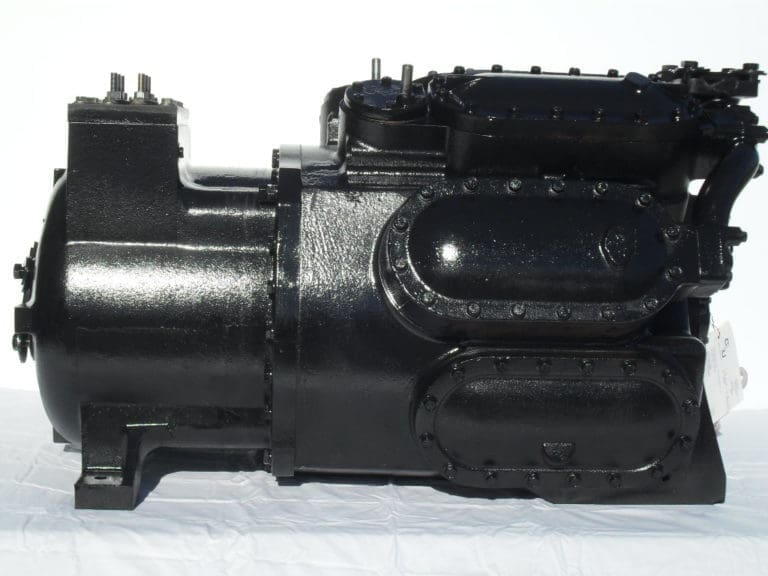

In contrast, remanufacturing is a comprehensive process that brings a compressor back to “like-new” condition. Every component, from the crankshaft to the valve plates, is inspected, cleaned, and replaced if necessary. This ensures the remanufactured commercial compressor meets or exceeds the original equipment manufacturer’s (OEM) standards for performance and reliability and allows the manufacturer to cover the compressor with their standard limited warranty.

What a Commercial HVAC/R Compressor Does

The compressor is the core of any commercial air conditioning system. It does the essential mechanical work of compressing the refrigerant gas. The compressor will work harder to compensate for mechanical wear and tear and other issues throughout the system. But when it fails, the entire air conditioning unit will grind to a halt.

The compressor is often called the heart of the system – and for very good reason.

In recent years, it has not been unusual for large organizations to maintain a stock of backup commercial HVAC/R compressors in the event of an unexpected equipment failure. Farms, meat processing plants, and even large grocery stores, like Kroger or Albertsons, can rely on dozens or sometimes hundreds of compressors to maintain perishable products at safe temperatures.

Whatever the case, every day spent without a functional commercial HVAC/R compressor can cost thousands of dollars.

The Remanufacturing Process for York Commercial HVAC/R Compressors

The remanufacturing process begins with the compressor’s core, which is thoroughly inspected for any damage. Components that are prone to wear, such as seals, o-rings, and bearings, are replaced with new ones. In some cases, the compressor core itself might need to be replaced if it’s beyond repair, but often, it can be restored, saving costs and reducing environmental waste, which is better for our landfills.

One of the critical stages in remanufacturing is the testing phase. At Compressors Unlimited, for example, remanufactured York commercial HVAC/R compressors undergo rigorous testing to ensure they perform as well as, or better than, new compressors. This includes leak testing by submerging the compressor to identify leaks and load testing to simulate real-world operating conditions.

Why Choose a Remanufactured HVAC/R Commercial Compressor?

Opting for a remanufactured York compressor can save you up to 30% compared to buying a new unit. Additionally, since remanufactured compressors are often available sooner than new ones, you can minimize downtime, which is crucial in commercial settings where HVAC/R systems are critical to daily operations.

Moreover, the remanufacturing process includes updates to incorporate the latest technologies and improvements, potentially enhancing the compressor’s efficiency and durability. This means you’re not just getting a compressor restored to its original state but one that might outperform the original.

Final Thoughts for Commercial HVAC/R Technicians

For commercial HVAC/R technicians, the decision to use a remanufactured York compressor is not just about cost savings and environmental impact. It’s also about ensuring reliability and maintaining system performance. By choosing a reputable remanufacturer, you can ensure that the commercial HVAC/R compressor will meet all necessary standards and that it will be supported by a warranty, giving you peace of mind in your operations.

When your facility’s HVAC/R system depends on the reliable performance of a York compressor, understanding the remanufacturing process and the benefits it offers is essential. It’s a solution that balances cost, efficiency, and sustainability, making it an excellent option for commercial applications.