For decades, HVAC systems have been equipped with conventional single-speed compressors. An HVAC system that uses a single-speed compressor switches on when the indoor temperature reaches a certain value. The compressor will continue to operate at full capacity until the indoor temperature decreases sufficiently. When the temperature matches the thermostat setting, the compressor turns off.

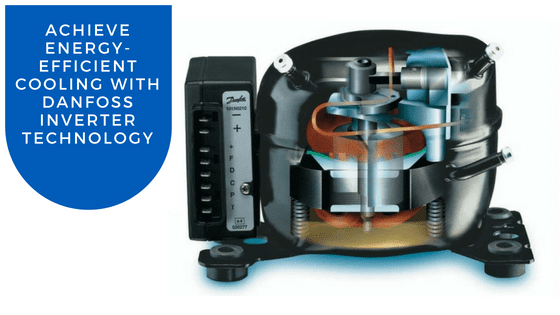

Unlike a conventional single-speed compressor, a Danfoss compressor equipped with the inverter technology is able to self-regulate its capacity in response to cooling demands. As a result, this type of compressor can efficiently maintain constant temperature and humidity levels throughout buildings.

Assessing the Benefits of the Inverter Technology

To begin with, the most important benefit of using an inverter-driven scroll compressor is that it accurately responds to changes in indoor temperatures. This translates into a number of benefits, including significant energy savings, enhanced thermal comfort, less wear and tear on system components, and lower greenhouse gas emissions.

Thanks to the inverter technology, also referred to as variable-speed technology, a Danfoss compressor can dynamically adjust its motor speed in real time, according to the fluctuating thermal loads throughout a facility. Because a Danfoss inverter scroll compressor is able to increase or decrease the air velocity, it allows for better temperature and humidity control, particularly under part-load operating conditions. Furthermore, it enables you to precisely control your indoor environment, irrespective of the weather and the activities performed indoors.

A variable-speed compressor also cycles on and off less frequently. In addition to maintaining constant temperature and humidity levels throughout buildings, fewer on and off cycles minimize energy consumption. Since a Danfoss inverter scroll compressor consumes less energy, it emits significantly less greenhouse gas over its lifetime compared to a conventional single-speed compressor.

Considering that Danfoss inverter scroll compressors gradually speed up and slow down to match thermostat settings, they don’t have to work too hard. As a result, the HVAC units that include a Danfoss inverter scroll compressor tend to suffer less wear and tear on their components. This makes them more durable than other comparable systems that use a conventional single-stage compressor.

Another important aspect is that Danfoss inverter scroll compressors can be paired with specific “zoning” devices, such as sensors, thermostats, and “dampers”. With the help of these devices, you can better optimize the temperature and humidity in selected zones and provide a higher level of comfort for your customers and employees.

Looking beyond the Danfoss Inverter Technology

Although the inverter technology is one of the most important pieces of the energy-efficiency puzzle in a commercial or industrial facility, the energy efficiency of an HVAC system depends on a few more factors, including:

- Choice of refrigerant – As surprising as it may seem, the energy efficiency of an HVAC system is impacted by the thermodynamic properties of the refrigerant used. Because some refrigerants are more suited for specific climate zones and applications, careful consideration should be given to the type of compressor and refrigerant specified for each application.

- Design – Inverter scroll compressors can be optimized for specific applications in order to improve the efficiency of your HVAC unit.

- Climate – Although the SEER rating of an HVAC system is the same no matter where you buy it, the actual SEER rating depends on how close the actual temperatures are to the standard conditions.

Nowadays, the inverter technology allows OEMs and independent compressor remanufacturers, like Compressors Unlimited, to provide a wide range of energy-efficient compressor models. Increasing energy efficiency and energy conservation demands have played a crucial role in the strategy development of Danfoss, which has become one of the world’s top compressor manufacturers of this game-changing technology. To discover the latest Danfoss products and technologies, feel free to contact our friendly professionals today at Compressors Unlimited!