Bearings are an important part of many kinds of precision machinery. For nearly 100 years now, bearings have been one of the most essential industrial products in the world, showing up in all kinds of devices. In a range of settings the average person would never consider, bearings are crucial – and that’s just as true when it comes to commercial HVAC compressors.

What Are Bearings in a Commercial Compressor?

In any machine, a bearing has two functions: To restrain relative movement to only the motion desired and to reduce friction in moving parts. Bearings and lubrication are the two major elements that work together, so a commercial compressor or other machine can function with a minimal amount of wear and tear.

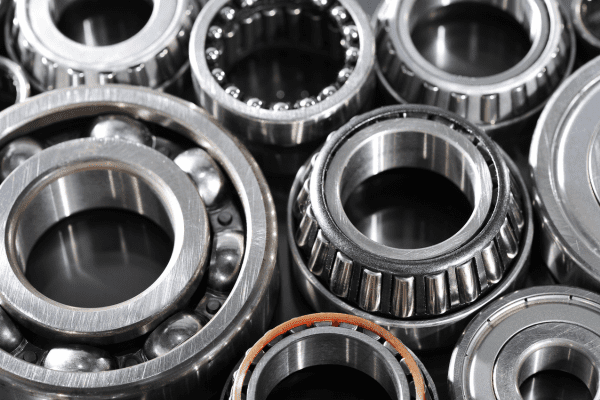

There are several different kinds of compressor bearings, and the exact kind your compressor uses will always depend on the make and model. Single-row ball bearings are one type of rolling-element bearing found in the screw and scroll compressor designs, reducing rotational friction and supporting both radial and axial loads.

From the simplest reciprocating compressor to the largest commercial centrifugal compressor, every type of HVAC and refrigeration compressor in the world has at least some type of bearings. In a reciprocating compressor, a design usually incorporates four different types of compressor bearings as follows:

- Main bearings, found between the frame and the compressor crankshaft

- Crankpin bearings, located between the connecting rod and the crankshaft

- Wrist pin bearings, set up between the connecting rod and the crosshead

- Crosshead bearings settled beneath the compressor crosshead itself

What Do Bearings Do In a Reciprocating Commercial Compressor?

Although bearings are found in all kinds of commercial compressors, they are especially important within a reciprocating commercial compressor. These compressors are “workhorses” based on a design that has the longest history in the compressor industry, and bearings provide several crucial services for them.

The benefits of reciprocating compressor bearings include:

Proper Rotor Placement

Rotor placement of a reciprocating compressor is one of the crucial factors ensuring you get the performance and service life you expect from the unit. The rotor supports the gas load, and the journal and thrust bearings manage the placement of the rotor throughout the cooling or refrigeration cycle.

Continuous Compressor Operation

Reciprocating compressors are not always used in continuous operation environments. When this becomes a requirement, however, its commercial compressor bearings come to the rescue. Specialized hydrodynamic bearings use a hydrodynamic “wedge” of oil to further reduce friction, greatly extending lifespan.

High-Speed Compressor Operation

In a reciprocating compressor, the major limit on high-speed operation is the amount of vibration that could result. Uncontrolled vibration has the potential to lead to early failure of a reciprocating compressor. With a proper compressor bearing, you can mitigate these issues and get more performance out of a compressor.

How Does the Heat Affect Commercial Compressor Bearings?

All commercial compressors have a standard operating temperature band and are designed to function within a particular climate. These tolerances are determined by OEM testing and take into account both the ambient air temperature and the usual level of humidity. However, even such guidelines are far from perfect.

At the top end of any of these ranges, there’s always the possibility of damage. As one of the smallest and most precisely engineered parts within a commercial compressor, compressor bearings are at the highest risk – and a compressor bearing failure can cause serious damage throughout the system.

Whenever a compressor operates in a hot environment, it may pull more electricity and work harder to achieve the same results. This leads to increased internal temperatures and results in a faster breakdown of lubricating oil. This problem can easily catch you off guard even if you do regular commercial compressor maintenance.

Although bearings can temporarily cope with extremely high temperatures, overheating causes damage after a short time. “Micro-cracks” can appear in the structure that aren’t visible to the naked eye but still have a very profound effect on the bearings. Even a brief overheating episode means bearings should be replaced.

Most compressor components aren’t designed for field replacement, but compressor bearings, like a commercial compressor’s o-rings, are an exception to this rule. You should always strive to have a variety of compressor bearings among the compressor spare parts you stockpile on hand to keep your unit running.

What Can You Do About Damaged Compressor Bearings?

If your commercial compressor bearings are damaged, replace them right away. Run appropriate tests to check on the rest of your commercial compressor functions and respond appropriately, especially during a hotter time of year. If damage is widespread, you may need to replace your commercial compressor.

Save time and money by purchasing your commercial compressor spare parts from a company that specializes in remanufacturing these important machines. When you have the parts you need, you could save yourself from having to replace your compressor before you need to.