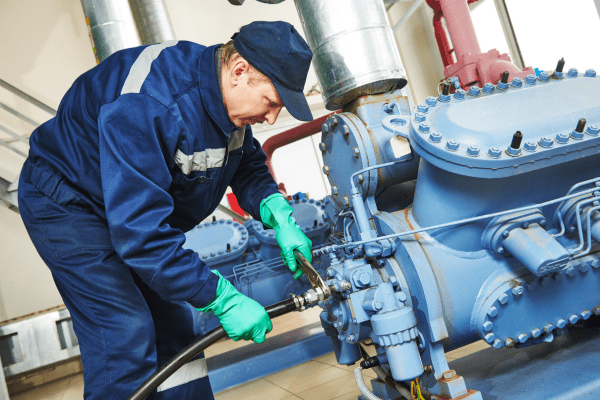

Bad compressor valves have plagued HVAC systems for ages. As with any moving part, valves wear down over time, allowing refrigerant to push past the seals and throw the system off balance. Often this leads to flooding and other conditions that cause the compressor to function less efficiently than it should. However, it can be very difficult to diagnose this issue from the outside because there are no visible indications that the compressor is suffering. That’s why you need to call in an experienced technician who can solve the problem, right down to the compressor core.

Signs of Bad Compressor Valves

For the most part, the user will only notice a bad compressor valve if the compressor becomes increasingly inefficient over time. Since this typically happens a little at a time, year over year, you may not realize the full extent of the damage on your own at all. Instead, it is typically maintenance technicians who discover the problem when conducting regular inspections of the system. Technicians use gauges to test the pressurization of the system and track system performance as it cycles on and off. These tests will clearly show that a compressor has bad valves if the system is getting flooded every time it turns on, or if there are obvious signs of refrigerant migration across the different sections of the compressor.

For a better understanding of this issue, you first need to know that your compressor has both a high pressure side and a low pressure side. It is this difference in pressures that allows the refrigerant to contract and expand, which cools your air. When valves start to go bad, refrigerant migrates from the high side toward the low side, which means that the pressure differences begin to equalize across the entire system. If the refrigerant is unable to contract and expand the way it is supposed to, then no cooling will occur. In addition, when liquid refrigerant reaches parts of the compressor that it should not be in, the compressor has a harder time starting up in the first place because it is fighting against an unexpected volume of refrigerant.

Why Are Bad Compressor Valves a Big Deal?

Obviously, a compressor that lacks efficiency will cost you money every time you have to rely upon it. Moreover, bad compressor valves can go on to cause other serious damage to your HVAC system, like excessive wear on other components. The fact is that compressor valves are a wearable part, and they are very fragile. They can easily be replaced when they start to wear down, but if you put off your maintenance for too long, you could find yourself paying for other costly repairs as well.

There is also a matter of overheating to be concerned with. When a compressor’s valves go bad, the system will overwork itself to the point that it begins overheating. This can lead to serious issues and damage to other parts of your system. The longer it goes on, the more likely you are to experience electrical issues inside of your HVAC unit as well.

It is easy to see how and why bad compressor valves can happen, and furthermore, why it is important to schedule regular inspections and maintenance for your compressors. The sooner you are able to identify bad valves, the easier it will be to get them fixed and avoid further damage that will lead to losses on your part. For more information, visit Compressor Unlimited today to see a full selection of parts and accessories for your HVAC system, and speak with one of our technical experts about how to take proper care of your valves.