One question that you will often hear with regard to commercial compressors is how much oil pressure they need to operate. The oil pressure required will depend on the size, type and intended use of the system. The age of your compressor may also affect oil pressure, because older compressors have more worn parts, which creates gaps that allow for extra oil to flow, thereby reducing pressure in the system. As you compare different compressor types and oil pressure requirements, it is important to understand the difference between useful or net oil pressure and discharge oil pressure. These two measurements apply to different parts of your system, and you must understand which is which to ensure that your compressor is properly lubricated and operating normally.

What is Discharge Oil Pressure?

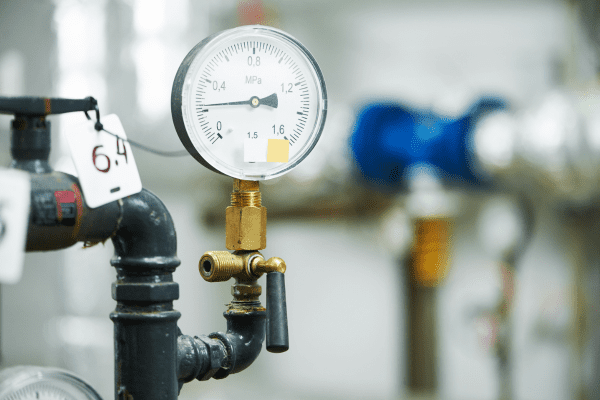

Before we can get to useful oil pressure, we first have to start with the oil pressure measurement that is easiest to find. The discharge oil pressure is the oil pressure that is measured at the discharge end of your compressor. This is important because this is the only place where you will be able to actually measure oil pressure with gauges, but it is not a true measurement of the oil pressure in your system. Rather, the discharge oil pressure is a combination of your input oil pressure plus your crankcase oil pressure, so it will be higher than the actual oil pressure you are working with.

Finding Your Net Oil Pressure

Once you have measured your discharge oil pressure, you can work backward to discover your net oil pressure. This is done by subtracting the crankcase oil pressure from your discharge pressure. You should be able to find the crankcase pressure of your system pretty easily because it stays stable. Thus, the only variation in your calculation will occur if the net oil pressure has increased or decreased.

For example, if you attach your pressure gauge to the high side at the discharge port, and you measure a PSI of 70, you will next need to look for your crankcase pressure. If standard crankcase pressure is 15 psi, you will know that 70-15 = 55. This is your net oil pressure.

Why Net Oil Pressure Matters

The net oil pressure of this system is the actual amount of pressure that is being created by the oil pump. Most compressors have a safe operating range that requires a minimum of 20 psi from the oil pump. If you measure the oil pressure at your discharge port, subtract the crankcase pressure, and discover that your net oil pressure is too low, it could mean that your compressor is operating without sufficient lubrication. It could also mean that the internal components of your compressor have worn down to a point that they are unable to maintain standard oil pressure during normal operation. Both of these are cause for concern. On the other hand, if you discover that your oil pressure is extremely high, it could be a sign that there is a blockage somewhere in the system which is forcing all oil to flow through limited space. This can be equally damaging and must be addressed in a timely fashion.

Knowing the difference between discharge oil pressure and net oil pressure will help you get an accurate reading of your system during maintenance. You do not want to mistake these two different measurements because they could lead you to improper conclusions regarding the state of your compressor. Properly measuring and maintaining the oil pressure in your commercial compressor, is a vital part to the health of your commercial compressor. Learn more commercial compressor maintenance tips today, by reviewing other helpful blog posts from Compressors Unlimited.