When you want longevity and reliability from a compressor, maintenance is essential. And to make the most of your maintenance routine, you need compressor spare parts you can trust. That’s true even if you use Carrier commercial compressors, well known for excellent performance and ease of use.

Carrier is one of the world leaders in compressor technology. But, just like other compressors, you can run into issues unless you have the right compressor replacement parts on hand. Here at Compressors Unlimited, we maintain a full stock of replacement compressor parts for all the top brands in the world.

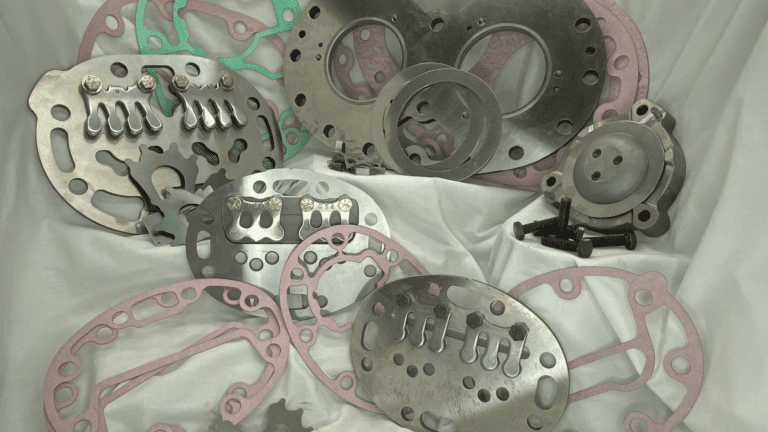

Our complete selection of Carrier spare compressor parts includes everything you need to keep your system running. You can get your Carrier unloaders, Carrier valve plates, Carrier crankcase heaters, as well as mainstays such as piston rings, bearings, suction and discharge service valves, gaskets, polyster oil, and alkbenzine oil.

If we don’t have what you need, we’ll source it quickly.

Some of the most commonly requested Carrier compressor parts include:

1. Carrier Valve Plates

The valve plates act as seals between the different pressure areas in a compressor. They typically include built-in intake and exhaust restrictor valves to help with the transfer of gas or liquid from one part of the system to another. They are among the most common parts in any commercial HVAC compressor setup.

Carrier valve plates are known to be highly reliable and resistant to wear and tear. Even so, you should always keep a full set of valve plates at the workplace. If valve plates wear out or become deformed, your Carrier compressor may not function until they are replaced. Plus, it will be at heightened risk of a catastrophic failure.

Valve plates must be sized precisely for the system you are using. They should not be considered interchangeable with other brands just because they are a basic part of a compressor’s configuration. Genuine Carrier valve plates will help your equipment last longer.

2. Carrier Terminal Assemblies

As with other electrical devices, a terminal assembly consists of the electrical conductor, terminal, and a seal connected to both components. Over the last few years, companies like Carrier and Copeland have updated their terminal assemblies to further protect them against environmental contamination.

3. Carrier 06E Electrical Bridge Kits and Jumper Bars

Carrier 06E semi-hermetic reciprocating compressors are perhaps the most popular the company makes. They are among the most common reciprocating compressors for demanding commercial and industrial applications. With authentic Carrier 06E electrical bridge kits and jumper bars, you’ll be prepared to diagnose and fix electrical issues to ensure optimal efficiency from the compressor.

4. Carrier Unloader Valves

At just four inches, the unloader valve is one of the smallest parts in the Carrier compressor, but it performs an indispensable function. It releases any trapped gas so that the compressor motor can restart. When the compressor motor fails suddenly, you may be able to restore the unit to service by replacing this part.

Get Your Replacement Carrier HVAC Compressor Parts from the Most Trusted Source

There are many companies out there claiming to offer Carrier compressor parts. But when you want genuine Carrier replacement parts that work exactly the way you expect them to, it’s crucial to use a source you can trust. Experienced compressor engineers should stand behind every component.

Compressors Unlimited has provided thousands of top-quality remanufactured commercial compressors to industrial and commercial customers. Because we’ve seen compressors at every stage of the lifecycle, we know which spare parts compressor technicians are likely to need at any given time.

Spare parts can make the difference between a short period of downtime and a major disruption that can be devastating to your business. When it all comes down to one small piece, you want to be sure that the component offers you the highest standards of performance available.

When Repair Just Won’t Do, Turn to Remanufactured Commercial Compressors

When you need to replace a Carrier compressor, it’s best to go with the same make and model that you started with. But this can be easier said than done when Carrier and its affiliated wholesalers may have months’ worth of backlogged orders.

When your business can’t wait, a remanufactured compressor is the solution.

Remanufactured commercial compressors undergo a complete engineering process to restore them to the environmental and performance standards you expect from a new unit. On completion, they will be prepared for another 8-10 years of service.

A remanufactured commercial compressor is disassembled, the unit is cleaned, and parts are replaced. Once reassembled, equipment is tested to simulate real operating conditions. After passing all quality checks, the compressor can be shipped right away—the whole process takes a matter of days rather than weeks or months. Plus, you continue to benefit from your remanufacturing team’s expertise throughout the whole life of your compressor.