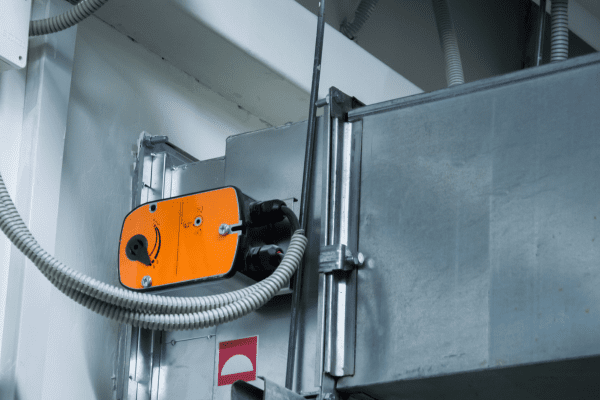

The damper actuator – also called damper motor in some cases – is the HVAC component used to control the opening and closing of the damper. The damper is a small valve or plate that helps to regulate airflow within a system. Without the damper actuator, there is no way to provide the necessary force to move the damper.

The combination of a damper and its associated damper actuator is used in a variety of industrial systems, but it is most common in the HVAC world. Electric, pneumatic, or hydraulic mechanisms can all be used to operate the damper actuator, and it enables highly precise control over the flow of air.

Temperature and air quality can both be influenced through an HVAC damper actuator:

- It can control the mixture of fresh (outside) and recycled air

- It can maintain, raise, or lower the temperature as desired

- It can control humidity levels

How Does an HVAC Damper Actuator Work?

The damper actuator moves in response to a signal from a control system, which provides information on the preferred position for the damper in response to temperature settings or airflow requirements in the building. Inside the actuator, the control signal is translated into the necessary movement.

The damper actuator continues to monitor for control signals so the damper can move at any time in response to changes in the conditions. In some cases, there are even manual override functions so that a technician can directly open or close the damper while bypassing the automatic control system.

Limit switches and fail-safe features are often incorporated into an HVAC damper actuator. These help to keep the damper from getting damaged during unusual operating conditions or even when the rest of the system is failing. For example, the actuator might be designed to return to a safe position if it loses the control signal.

Types of HVAC Damper Actuators

Although the most common HVAC damper actuator these days is the electric type, several others exist. The other varieties of damper actuators all have their own pros and cons. If you encounter another kind of damper actuator in the field, odds are good it was designed a certain way on purpose to serve the system’s needs.

The most common types of HVAC damper actuators include:

Electric HVAC Damper Actuators

Electric HVAC damper actuators are known for using an electric motor to control the opening and closing of the damper. The electric motor generates the appropriate rotational force after receiving a control signal. The usual design employs a gear train to convert the rotational force into the precise movement to the desired position.

Pneumatic HVAC Damper Actuators

Compressed air acts as the motive force in the pneumatic HVAC damper actuator. The pressure of the air drives the diaphragm or piston, moving it, and the movement is transferred to the actuator. The amount of air can be moderated to deliver precise control over the actuator’s movement.

Hydraulic HVAC Damper Actuators

The hydraulic HVAC damper actuator is the least typical and is more likely to be seen within the largest scale systems. A hydraulic pump is used to pressurize fluid within a closed system, moving the mechanical parts – a piston is most common. Control signals open or close valves within the actuator to control the movement.

Damper Actuator Maintenance and Damper Actuator Troubleshooting

Damper actuator maintenance tips are nothing too out of the ordinary compared to other forms of regular HVAC maintenance or HVAC commercial compressor maintenance. First and foremost, make sure you inspect the actuator so you can spot signs of corrosion, wear, and other problems before they impact performance.

Lubricate parts regularly according to manufacturer instructions to keep friction from causing damage. Calibrate the actuator on a quarterly or twice-annual basis to ensure it continues to respond appropriately to the signal from the control system. You may need to double-check alignment and clean off feedback sensors.

Regularly check the filters, ensure the fluid or air is clean, and test the pressure levels if you use a hydraulic or pneumatic actuator. Remember that, just like the HVAC filters elsewhere in the system, you will need to clean or replace any actuator filters and should know exactly how to handle them when the time comes.

The damper actuator is one component that can cause outsize problems with your HVAC system if it stops working. But what if you diagnose a problem only to discover it’s actually the HVAC compressor at fault? In cases like these, a remanufactured commercial compressor is your best bet.

With a remanufactured commercial compressor, you can enjoy a savings of 10%, 20%, or even more over the new HVAC commercial compressor cost from an OEM-affiliated wholesaler. You get a unit that’s ready for another decade while cutting your new HVAC compressor procurement time from months to weeks.