Whether you are running a refrigeration system or commercial air conditioning, a compressor unit is essential to all cooling functions. The compressor is the key component that enables refrigerant gas to move through the system. If it fails, the entire cooling system comes to a stop – no matter the details.

Whether you are running a refrigeration system or commercial air conditioning, a compressor unit is essential to all cooling functions. The compressor is the key component that enables refrigerant gas to move through the system. If it fails, the entire cooling system comes to a stop – no matter the details.

Compressors are also essential to heating functions in a large commercial HVAC system. However, they are most often thought of in terms of cooling. Losing the ability to cool a building during the summer can prompt fast complaints. And when refrigeration fails, thousands of dollars in products are usually on the line.

When you compare different types of cooling compressors, there are three things to bear in mind:

- Maintenance

- Technology

- Brand

Once you have made choices in these three areas, you can focus on finding a compressor that offers the size and output you need. While there are some relatively easy choices in compressor selection, most of the decisions you’ll make are complex. Each choice weighs on your system’s longevity and performance.

Cooling Compressor Maintenance Technologies

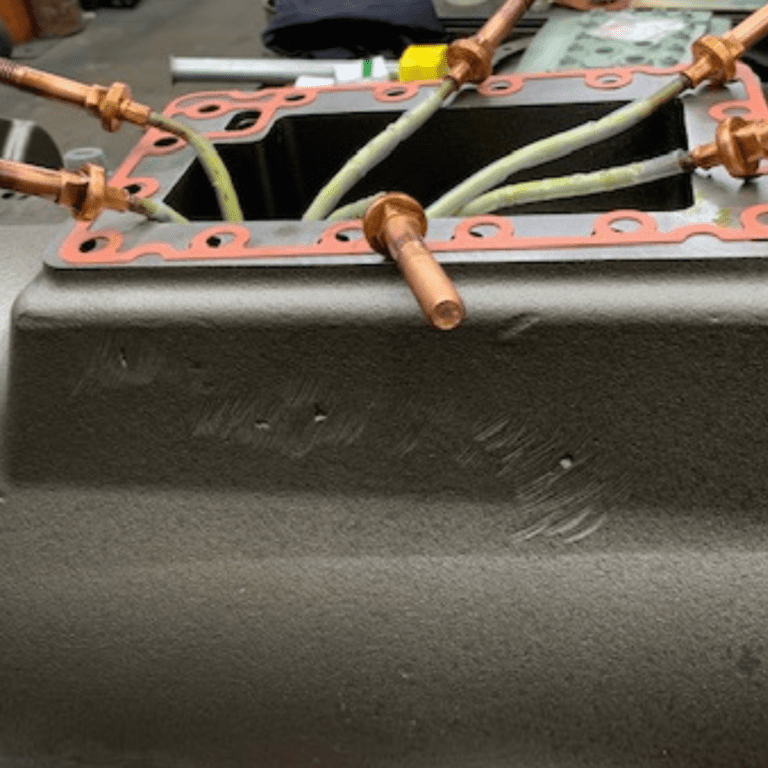

Commercial cooling compressors can be either hermetic, semi-hermetic, or open.

Early compressors used a hermetic design. The motor and compressor were housed in a single welded steel shell. A hermetic compressor, like a Danfoss SH model, tends to have a shorter service life – as little as three years – because the housing cannot be opened to perform maintenance. This is common in consumer-grade systems.

For mid-sized and large cooling systems, you’ll usually look for a semi-hermetic cooling compressor, like a Carrier 06E model. With these models, the motor and compressor are housed together, but the casing can be opened to perform maintenance as needed. This significantly improves the lifespan of the system.

An open compressor, like the Carrier 5H series, uses an external motor that drives a shaft passing through the compressor. These can be prone to failure of the rotary seals around the shaft, which are needed to maintain the pressure.

The Most Common Cooling Compressor Designs

Cooling compressors are differentiated by the specific mechanism they use to compress the refrigerant gas. The compression method affects all the performance qualities of the compressor, so the rest of the system must be designed within the tolerances that it requires.

The basic cooling compressor designs include:

1. Reciprocating Compressor

A reciprocating compressor is the simplest type of compressor in wide use today. The refrigerant gas is compressed through positive displacement using a piston. The piston becomes the compressor’s main point of failure because of the intense mechanical pressures it must endure during operation. Welded hermetic compressors can have a very small footprint, making them ideal for specialty applications.

2. Scroll Compressor

A scroll compressor uses a circular motion produced by a pair of aligned scrolls. One scroll is attached directly to the compressor’s body, while the other, connected to the crankshaft, orbits around it. Gas pockets form and move toward the scroll’s center, where pressure gradually increases. It experiences much less vibration and surging than a piston compressor, making it both more efficient and quieter.

3. Screw Compressor

Screw compressors, like the Trane CHHB series, are positive displacement devices that often replace piston compressors in large-scale industrial cooling due to their superior efficiency. Compression is achieved by a rotary screw in a continuous sweeping motion. The design combines a simple structure with a larger capacity and higher efficiency than a comparable scroll unit. It is also less sensitive to liquid slugging.

4. Centrifugal

Also called a “turbo” or “radial” compressor, it uses rotating impellers to add kinetic energy to refrigerant that passes through the impellers and ultimately into the diffuser. As impeller speed increases, so does pressure. Centrifugal compressors are known for their high capacity and great partial load efficiency. Operation and maintenance tend to be less costly due to lower number of parts.

The Leading Commercial Cooling Compressor Brands

When you are choosing a cooling compressor, the brand is an essential consideration. Even within the same design family, different brands use varying components, approaches, and technologies.

For example, two brands might offer a scroll compressor with similar output but using a different type of refrigerant gas. The cost, availability, and environmental properties of the refrigerant, in turn, affect the value you can get from the compressor, even if two compressors share many similar traits.

Carrier is the cooling compressor brand with the longest history in the U.S., serving as the originator of the modern cooling compressor. Another popular option is Trane, founded more than a century ago in Wisconsin. The wide availability of parts and qualified maintenance make these units easier to care for.

Many commercial enterprises aim to improve ease of maintenance by purchasing commercial cooling compressors exclusively from one manufacturer. Whatever you choose, remanufactured commercial compressors can save you time and money. Buying a remanufactured compressor means getting reliable cooling quality from a brand of your choice at a significant discount and much faster than buying from OEM-affiliated wholesalers.