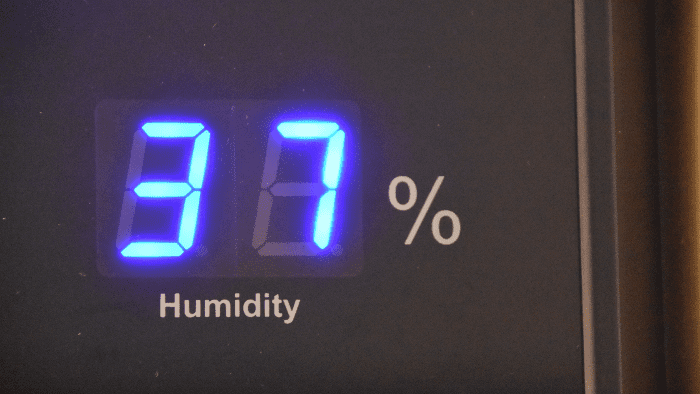

High humidity is one of the most significant dangers that can damage a commercial compressor and even cause it to fail before its time. Humidity can have a profound impact on the compressor even when its environment is otherwise ideal and it is always used according to its optimal workload.

Despite this, humidity often goes unnoticed as a factor until concerning symptoms develop. Some customers in the South and Southwest, in particular, report they are dealing with higher levels of humidity than they used to or expected when they originally purchased their current compressor.

While it’s crucial to always use the same make and model of compressor your system was originally designed to include, you should keep an eye out for the telltale signs that humidity is overwhelming your compressor. This is one of the most important environmental variables you might have to take action to control.

How Do You Know if Humidity Is Having a Negative Effect on Your Compressor?

When humidity damages a compressor, many of the symptoms are things that could also happen as a result of other environmental, electrical, or mechanical issues. With that in mind, you might need to perform a complete inspection to be sure humidity is the real culprit. Still, any of these signs can point to a humidity problem:

1. Corrosion

Modern commercial compressors and the refrigeration or cooling systems they serve are designed to minimize the risk of corrosion, but humidity puts those defenses to the test. As condensation forms, there is a far higher risk that the metallic parts of the compressor will corrode, weaken, and ultimately fail.

A visual inspection of all metallic parts of the compressor, including the housing and the coil windings, will help you find signs of corrosion. Semi-hermetic (and, of course, hermetic) compressors enjoy greater protection but aren’t immune. Plus, the build-up of fluid can lead to more serious issues, like flooding and slugging.

2. Electrical Failures

Tripped circuit breakers often offer you the first clue that something is wrong with your electrical system, but it can be hard to pinpoint the issue from there. Electrical problems should be a top priority because replacing a compressor in a compromised electrical environment will just lead to more damage in the new compressor.

Root cause analysis is advised here, but don’t hesitate to examine the compressor itself as one of your first steps. The condensation that develops as a result of high humidity can seep into the compressor’s electrical components and cause damage that may require a replacement compressor.

3. Increased Workload

No matter whether your compressor operates an HVAC or a refrigeration system, increased ambient humidity will cause the system as a whole to work harder. You might notice an increased number of cooling cycles, for example, with a lot more power used to reach the target temperature.

Any time the system is in operation, the commercial compressor is providing the mechanical effort necessary to drive the refrigeration cycle. A system that’s working 10%, 20%, or 30% harder is effectively turning over all that extra work to the compressor, which may burn out if it is now exceeding its tolerances.

4. Increased Friction

Maintaining appropriate lubrication levels is an essential basic maintenance task that keeps a compressor from succumbing to wear and tear. This is especially important for reciprocating compressors, while it may be a lesser-issue for some of the most sophisticated screw compressors on the market today.

High levels of humidity have the potential to dilute a compressor’s lubricant oil. This can happen even if you recently changed the oil and are confident it is at appropriate levels. Depending on the architecture, components throughout the system may be absorbing wear and tear that can lead to performance problems.

Compressor Maintenance Is Key – So Is Knowing When to Replace a Commercial Compressor

Modern compressors are more durable and reliable than their counterparts in previous generations. It’s not out of the ordinary for a commercial compressor to deliver 8-10 years of steady service when maintained regularly. Today’s top compressor manufacturers are known for units that remain efficient far into the second half of life.

Sooner or later, though, commercial compressor replacement is inevitable.

Once you’ve narrowed down the cause of the problem and done what you can to mitigate ambient humidity, take time to honestly assess the compressor’s performance and the extent of the damage. Some issues, like corrosion, can be completely repaired, while electrical short circuits leave you vulnerable to future problems.

When compressor replacement is near, a remanufactured commercial compressor is the best option for time and budget.

Using your existing compressor core as a base, a remanufactured commercial compressor is fully disassembled, has all necessary replacements made, and is tested in every function. This leads to a substantial discount and weeks or months off your total fulfillment time.