When it comes to running a successful business, maintaining a reliable HVAC/R (Heating, Ventilation, Air Conditioning, and Refrigeration) system is crucial for comfort, safety, and product preservation. Yet, commercial owners may overlook how the power source, specifically generators, can impact critical HVAC/R components like the compressor. In this blog, we’ll explore how your generator can affect the performance, lifespan, and reliability of your HVAC/R commercial compressor and highlight key aspects to ensure they work together smoothly.

1. Power Quality: Why It Matters

One of the most essential factors in running HVAC/R compressors effectively is a consistent and high-quality power supply. Generators, however, may not always deliver the same level of power quality as a regular utility source. Issues like power surges, voltage fluctuations, and harmonic distortions can occur when generators operate, especially if the generator is undersized, overloaded, or not adequately maintained.

Compressors are sensitive to these fluctuations. Voltage spikes or dips can cause overheating, damaging windings, and even lead to burnout over time. When commercial HVAC/R compressors run on inconsistent power, they may work harder than necessary to maintain proper cooling and heating functions. This added strain reduces their operational lifespan and can result in frequent and costly repairs or replacements.

Tip for Business Owners: Invest in a high-quality generator with voltage stabilization and consider additional equipment like surge protectors and voltage regulators. Regular maintenance and load assessments are also essential to keep the generator operating optimally, which, in turn, protects your compressor.

2. Generator Sizing and Compatibility with Compressor Load

The power needs of an HVAC/R system vary, especially when compressors start-up. During startup, compressors require a significant amount of current, often called “inrush” current, which can be 2 to 6 times higher than the regular running current. If your generator isn’t properly sized to handle this inrush demand, it may lead to frequent tripping or, worse, compressor damage due to insufficient power.

An undersized generator can struggle to maintain the necessary voltage during startup, causing the compressor to stall or draw more current than usual, which stresses both the compressor and the generator. On the other hand, an oversized generator may operate inefficiently and increase fuel consumption, impacting operational costs.

Tip for Business Owners: Work with a professional to assess your HVAC/R system’s power needs, focusing on the compressor’s startup requirements. Choose a generator sized to handle this demand comfortably. Investing in soft starters or variable frequency drives can also help manage inrush current by gradually ramping up the compressor’s power needs, reducing stress on both the compressor and generator.

3. Frequency Stability and Compressor Performance

The frequency stability of your generator is another critical aspect. Standard HVAC/R compressors are designed to run on a specific frequency, usually 50Hz or 60Hz, depending on the region. When the frequency fluctuates outside the acceptable range, the compressor’s motor speed can vary, affecting its efficiency and cooling performance. Over time, frequency instability can lead to overheating, reduced cooling capacity, and shortened compressor lifespan.

Generators without advanced frequency control mechanisms may struggle to maintain a steady frequency, especially during fluctuating load conditions. This is particularly true for older or poorly maintained generators that may experience more frequent RPM variations.

Tip for Business Owners: When selecting a generator, opt for models with advanced frequency control, such as those with an Automatic Voltage Regulator (AVR) or Inverter technology. These features help to maintain a consistent frequency, ensuring your HVAC/R compressor operates within safe parameters, leading to fewer issues and extended equipment life.

4. Fuel Quality and Generator Health

The quality of fuel used in generators directly impacts their efficiency and lifespan, which in turn affects the HVAC/R compressor. Low-quality fuel can cause the generator to run inefficiently, leading to unstable power output, including voltage and frequency fluctuations, which are harmful to compressors.

Dirty fuel can cause clogging in the generator’s fuel lines, filters, and injectors, ultimately leading to erratic power output or, in severe cases, generator breakdowns. This directly impacts your compressor, which may experience power interruptions, affecting its operation and reliability.

Tip for Business Owners: Regularly inspect and maintain your generator’s fuel system. Only use high-quality fuel, as it ensures better power stability. Consider installing fuel filtration systems or conducting periodic fuel testing to minimize contamination and prolong generator health.

5. Temperature Management: Keeping Both Systems Cool

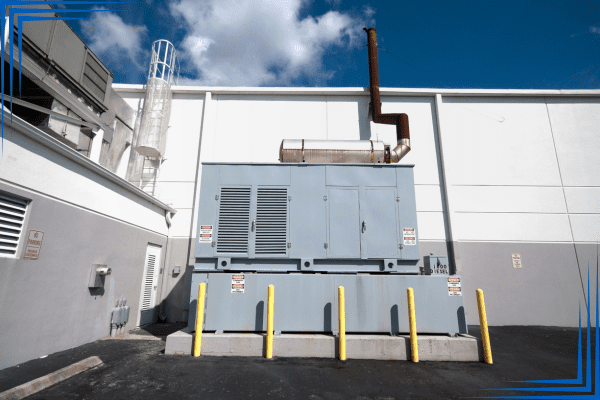

Both generators and compressors generate substantial heat during operation. If your generator and HVAC/R systems are situated in close proximity or confined spaces, heat buildup can become an issue, reducing the efficiency of both units and potentially leading to overheating.

Overheated compressors are prone to rapid wear and tear, as well as mechanical failures, and they require more frequent maintenance. The generator, too, suffers in high-temperature environments, which can lead to inefficient operation and increased fuel consumption.

Tip for Business Owners: Ensure that both your generator and HVAC/R compressor have adequate ventilation. Consider dedicated cooling solutions or install fans to improve air circulation. In cases where both systems operate simultaneously for long periods, remote monitoring of temperature levels is beneficial.

6. Maintenance Practices for Long-Term Synergy

Regular maintenance is essential to maximize the lifespan of both your generator and HVAC/R compressor. Scheduled inspections, cleaning, and timely repairs help avoid sudden breakdowns that could disrupt business operations. When a generator and compressor are maintained properly, they work more efficiently and with reduced risk of damage from irregular power.

Tip for Business Owners: Create a maintenance schedule for both your generator and HVAC/R system. It’s wise to conduct inspections with a professional to detect and address any potential issues early. Investing in preventative maintenance now can help prevent costly repairs down the line and ensure that both your generator and compressor perform optimally.

Investing in Synergy

Your generator and HVAC/R compressor play vital roles in keeping your business running smoothly, but they require proper alignment to do so effectively. By understanding the connection between these systems and addressing potential issues proactively, you can ensure reliable, efficient, and long-lasting performance.