York commercial compressors have a reputation as some of the best on the market.

With many years of experience and lots of great innovations behind it, the York brand stands shoulder to shoulder with the likes of Carrier, Copeland, and Trane. That said, it is always important to make sure you get the right commercial compressor model for your specific system needs.

That becomes even more crucial when you are sourcing a replacement compressor.

There are several different York models out there, and they can appear very similar at first. Often, you will see technical specifications that look nearly identical. Thanks to the long history of engineering evolution at York, however, apparently similar models can have significant differences.

Look closer and you will see they deliver that performance through very different means.

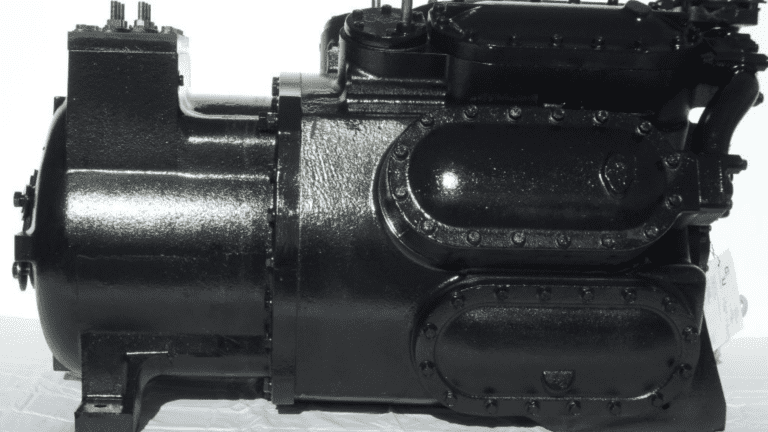

Nowhere is this more obvious than when it comes to the York JG commercial compressor.

The York JG Is a Completely Re-Imagined Version of One of York’s Most Popular Compressors

The York JG commercial compressor model is a direct response to some of the major concerns customers had with the earlier York JS compressor. Yet, if you compare the two piece by piece, they aren’t as similar as they might seem. The York JG has better performance overall with an innovation-forward design.

With the York JG, the old-fashioned loading and unloading process that relied on oil pressure has been changed completely. This was a driver of significant mechanical issues in years gone by. When problems struck, it was difficult to diagnose the root cause and often challenging to come up with a solution.

With York JG, you’ll see new engineering approaches for some core processes, including loading and unloading.

The biggest results of these changes are:

-

There are fewer points of fault, and issues throughout the compressor are easier to diagnose

-

The compressor is easier to maintain and therefore can remain in service longer than before

The York JG hasn’t gone without some short cycling woes, but these are faced only by the earliest JG model compressors. In place of the steel unloader piston deployed with the original JG, successive versions have used a much lighter aluminum piston that operates as expected under a wide range of conditions.

The Big Difference that Makes the York JG Compressor More Durable and Reliable than Ever

The best example of engineering foresight in the York JG cuts right to the heart of earlier generations’ issues.

The shift to using suction cutoff was a big move for York and originated right in the JG model. With suction cutoff, loading and unloading are smoother than ever. When you need to unload, you cut suction gas off from the port that feeds the cylinder and pass it through the solenoid at the top of the aluminum piston.

The imbalance in discharge pressure pushes the piston down into the suction port.

When it is time to load the compressor, high pressure gas is cut off from the solenoid and allowed to bleed off. Eventually, the balance of pressure changes until the suction gas pushes the piston back up. This opens the suction port and allows for the normal operation of the compressor.

This deceptively simple approach has a huge impact on overall compressor operations. It is overall a cleaner, more streamlined design and makes it far easier to diagnose compressor problems. In fact, suction cutoff has proven so valuable that York will institute it in all their new compressor designs going forward.

If you want a modern compressor that’s easy to use and maintain, the York JG is a solid choice.

A Remanufactured York JG Compressor Gets You Back in Action Quickly and Affordably

Many organizations are setting aside their older York compressors in favor of a York JG replacement compressor. With high energy efficiency and low cost of ownership, the JG comes highly recommended. We have heard from many customers that it makes their regular maintenance routines easier than ever before.

While the York JG is a valuable piece of equipment, don’t be tempted to pay more than you have to.

The difference between a compressor from an OEM-affiliated wholesaler and a remanufactured commercial compressor can mean thousands of dollars. Even more crucial, if you need to make an emergency replacement you can source a remanufactured compressor weeks to months sooner.

A trusted remanufacturer will get your refrigeration or cooling system back to work fast.

During remanufacturing, a compressor is completely disassembled and inspected according to the highest standards of engineering quality. All components are checked and replacements are made. The unit undergoes a thorough cleaning inside and out. The reassembled unit is also tested to ensure excellent performance.

The York JG compressor is a template for the future of York products. Now is the best time to experience it for yourself.