Industrial HVAC compressors are essential components of any large-scale heating, ventilation, and air conditioning system. These compressors are responsible for compressing refrigerant gas, which is used to cool and dehumidify air in industrial and commercial buildings. In this blog post, we’ll explore the basics of industrial HVAC compressors, their types, and their applications, as well as the industries that rely on them.

Basics of Industrial HVAC Compressors

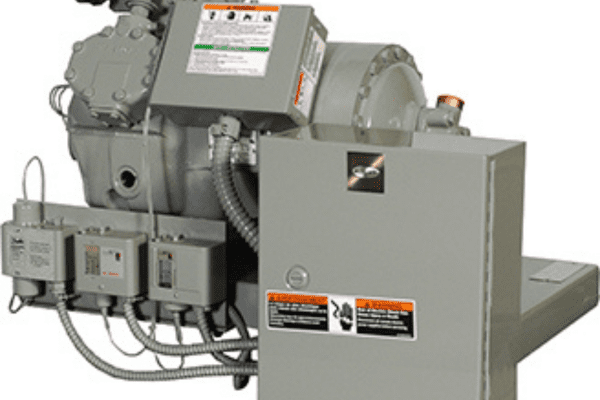

An industrial HVAC compressor is a machine that compresses refrigerant gas from a low-pressure state to a high-pressure state. The compressed refrigerant is then sent to a condenser where it is cooled and condensed into a liquid. This liquid refrigerant is then sent through an evaporator where it absorbs heat from the air, cooling and dehumidifying it, before being sent back to the compressor to repeat the cycle.

Types of Industrial HVAC Compressors- Keeping your industrial system in prime working condition is a must.

There are several types of industrial HVAC compressors, including:

- Reciprocating Compressors: These compressors use a piston to compress the refrigerant gas. They are commonly used in smaller commercial HVAC systems, such as those found in smaller commercial buildings.

- Screw Compressors: These compressors use two interlocking screws to compress the refrigerant gas. They are commonly used in larger HVAC systems, such as those found in larger commercial and industrial buildings.

- Centrifugal Compressors: These compressors use a high-speed impeller to compress the refrigerant gas. They are commonly used in very large HVAC systems, such as those found in industrial plants and manufacturing facilities.

Applications of Industrial HVAC Compressors

Industrial HVAC compressors are used in a wide range of applications, including:

- Dairies: Industrial HVAC compressors are used to cool the fresh milk that is stored onsite while waiting for transport. Not only are these compressors relied on for the quality of the milk being stored but they are also relied on for other farm equipment such as the milking machines that extract milk from the cows in large quantities.

- Government Facilities: Industrial HVAC compressors are used to cool the air in various government facilities to ensure personnel are comfortable during their long-extended work days. The temperature in these facilities are closely monitored based on their mission. Some facilities such as those that are responsible for public health have to ensure their industrial refrigeration equipment is fully functional at all times. If the temperature rises above a certain level, it becomes critical to the substance that is being kept cool, such as vaccines . Depending on the type of need of the facility, if the compressor were to fail which would result in inadequate cooling, catastrophic events could occur.

- Hospitals: Industrial HVAC compressors are used to maintain the air quality and temperature in hospitals to ensure the health and comfort of patients and staff. Not only are the comfort of patients and staff an important factor but it also plays a role in their health and safety. Warmer temperatures are more favorable for bacteria growth which is not ideal for a sterile environment like that of a hospital. Keeping the facility cool also reduces humidity levels, which prevents slips and falls. A humid floor is a slippery floor.

Types of Refrigerants Used in Industrial HVAC Compressors

The type of refrigerant used in an industrial HVAC compressor can vary depending on the application and the regulations in the region. Common refrigerants used in industrial HVAC compressors include R-22, R-410a, and R-134a. However, due to environmental concerns, many regions are phasing out the use of certain refrigerants, such as R-22 and R134a, in favor of more environmentally-friendly options.

Energy Efficiency of Industrial HVAC Compressors

The energy efficiency of an industrial HVAC compressor can have a significant impact on the energy consumption and operating costs of a building. Compressors that are more energy-efficient can help reduce electricity usage and costs, while also reducing greenhouse gas emissions. When selecting an industrial HVAC compressor, it’s important to consider its energy efficiency rating and any available incentives or rebates for installing energy-efficient equipment.

Maintenance and Repair of Industrial HVAC Compressors

Like any mechanical equipment, industrial HVAC compressors require regular maintenance to operate at peak efficiency and to prevent breakdowns. Regular maintenance tasks may include checking refrigerant levels, replacing filters, inspecting belts and bearings, and cleaning the compressor housing. In addition to regular maintenance, compressors may require occasional repairs or part replacements due to wear and tear.

Industrial HVAC compressors play a critical role for large-scale heating, ventilation, and air conditioning systems. They are available in various models, as well as brands, and are used in a wide range of applications, including manufacturing facilities, data centers, and hospitals. Understanding the basics of industrial HVAC compressors can help facility managers and HVAC technicians select the appropriate compressor for their specific needs. Many choose to use remanufactured compressors for expedited delivery as well as being cost effective.