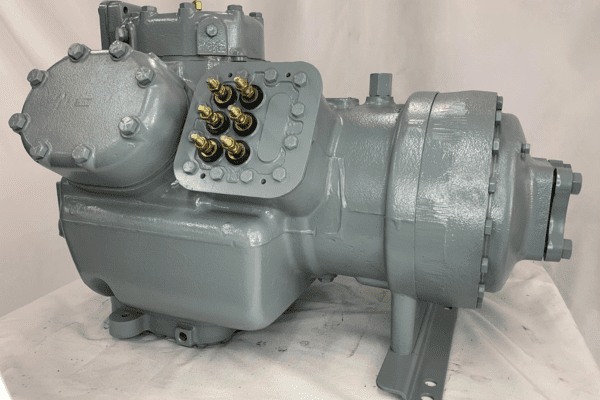

The Carrier 06E commercial compressor is among the most trusted on the market today. One of the most popular models is the 06ET275360 model.

Carrier is one of America’s foremost commercial compressor brands, and the Carrier 06E model, in particular, has developed a big following. Businesses that rely on their compressors often stick with the same Carrier model for years at a time. It is synonymous with a cost-effective service you can trust.

The Carrier 06E reciprocating compressor unit can be used within a refrigeration or air conditioning system. Once the unit is delivered, installation is fast and easy. The motor compressor and control center are fully pre-wired and mounted. It is compatible with a wide variety of evaporative, air-cooled, or water-cooled condensers.

Certain advanced engineering features help the Carrier 06E commercial compressor to stand out:

- Positive displacement oil lubrication through a high-flow oil pump with an auto-reversible design

- Highly reliable electronic oil pressure switch

- Improved refrigerant flow and reduced pressure fluctuation due to highly efficient valves

- Safe lubrication assurance even during flooded starts thanks to the oversized sump

With all of these great features and more, many organizations conclude that the Carrier 06E is the right solution for them on the long term. However, even these beautifully built machines have a specific service life they are unlikely to exceed. Sooner or later, you will have to replace your commercial compressor.

Save Money by Replacing a Commercial Compressor at the Right Time

Companies small and large are often in the position of deferring replacement costs for as long as possible.

In the case of a compressor, investing in maintenance can extend service and maintain quality, benefiting your budget in the long run. A compressor can be expected to run anywhere from 8-10 years on average, assuming an appropriate operating environment and a dedication to compressor maintenance.

As a compressor ages, mechanical wear and tear drives down overall efficiency. Maintenance sustains top-level performance for a longer period of time. Still, it is a wise idea to make preparations for the replacement. It is always best to replace a compressor on your terms, not when a disaster strikes!

At the same time, enterprises can avoid wasting money by keeping compressors in service for as long as is realistic. A balancing act is in play whenever you need to replace a commercial compressor: You are looking at both its output and its projected service horizon so you can buy when it makes maximum financial sense.

Replacement comes, even for the Carrier 06E. So how do you know for sure when the time is right?

Surefire Signs Your Carrier 06E Needs to Be Replaced

Barring catastrophe, a commercial compressor that is cared for properly does not fail early in its lifespan. The signs that replacement is looming tend to be more subtle. The better you know your compressor and how it works, the easier it will be to notice those clues before they develop into performance issues.

Let’s take a closer look at the symptoms of impending compressor replacement:

1. Your Compressor Is Aging Out

Even the best compressors do not always make it all the way to Year 10. You should have a replacement plan ready as the unit approaches its seventh year of service. That’s true even if you don’t notice a measurable change in performance. Rising energy consumption can also suggest that age is catching up with your system.

2. Your Repair Costs Are Rising

Standard maintenance should generally remain flat in cost over the years, but repairs can mount. If you notice you are replacing more components than before, your compressor may be on the way out. Like any mechanical system, there is only so much you can do to keep things running.

3. Building Issues Affect Your Compressor

A compressor’s output can be affected by a range of issues arising from the work environment. In old buildings, for example, wiring problems can introduce improper voltages to the cooling system, causing damage. When you uncover a problem like this, bear in mind it could have affected your compressor for years already.

4. Your Cooling Needs Change Dramatically

If you’ll soon need more refrigeration or air conditioning capacity, it is always best to go with a commercial compressor replacement rather than push an aging system to the edge of its design tolerances. The harder a compressor works, the more quickly it will go out of service, so keep an eye on average and peak demand.

When it’s time to retire your current Carrier 06E, consider a remanufactured commercial compressor.

A complete remanufacturing process that includes full inspection, cleaning, and replacement of critical parts gives you performance comparable to an all-new unit for the next 8-10 years of your business. It’s the Carrier quality you’ve come to expect at a small fraction of the price – and it can be delivered weeks faster, too.