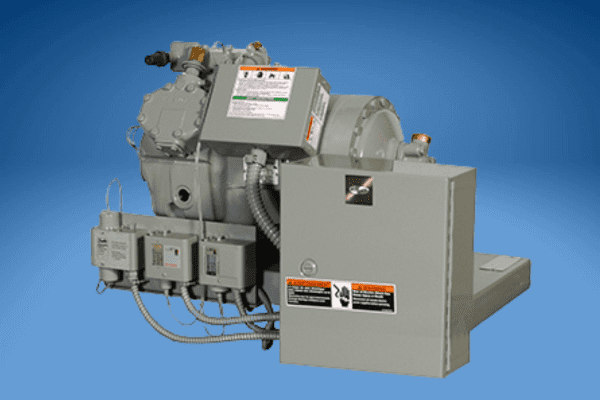

As commercial HVAC/R technicians, you understand the importance of reliable, high-performance compressors in maintaining optimal system functionality. Among the numerous compressor models on the market, the Carrier 06E series has long been a staple in the industry due to its robust design and reliability. However, the high cost of new units can be prohibitive, leading many to consider remanufactured options. In this blog, we’ll explore how to maximize performance using remanufactured Carrier 06E compressors, providing insights into their benefits, best practices for installation, and key maintenance tips.

Understanding the Value of Remanufactured Compressors

Remanufactured compressors offer a cost-effective alternative to brand-new units, making them an attractive option for commercial HVAC/R systems, especially in large-scale applications where budget considerations are paramount. But what exactly does “remanufactured” mean? Unlike simple repairs, remanufacturing involves a comprehensive process where the compressor is disassembled, inspected, cleaned, and rebuilt with new or remanufactured components. This process ensures that the compressor meets or exceeds the original manufacturer’s specifications, providing a reliable solution without the high price tag of a new unit.

For the Carrier 06E series, a remanufactured compressor can deliver the same level of performance and longevity as a new one if sourced from a reputable remanufacturer. These units undergo rigorous testing to ensure they can withstand the demands of commercial HVAC/R systems, making them a dependable choice for technicians seeking quality and value.

Benefits of Remanufactured Carrier 06E Compressors

- Cost-Effectiveness: Remanufactured compressors are typically 30-50% less expensive than new units, offering significant savings without compromising on quality. This makes them an excellent choice for budget-conscious projects or clients.

- Environmental Impact: By choosing a remanufactured compressor, you’re contributing to sustainability efforts. Remanufacturing reduces waste and conserves resources, as it reuses existing components rather than requiring new raw materials.

- Performance and Reliability: When properly remanufactured, Carrier 06E compressors perform on par with new units. Reputable remanufacturers will replace all worn or damaged parts and thoroughly test the compressor to ensure it meets original performance standards.

- Availability: In some cases, new compressors may have long lead times due to manufacturing delays or supply chain issues. Remanufactured units are often more readily available, reducing downtime and ensuring your clients’ systems are back up and running quickly.

Best Practices for Installation of the Carrier 06E

To maximize the performance of a remanufactured Carrier 06E compressor, proper installation is crucial. Here are some key steps to follow:

- Pre-Installation Inspection: Before installing the compressor, thoroughly inspect it for any signs of damage during shipping. Check for oil leaks, damaged wiring, or any other visible issues. If you notice anything out of the ordinary, contact your supplier immediately.

- Verify Compatibility: Ensure that the remanufactured compressor is compatible with the system in which it will be installed. This includes checking the voltage, capacity, and refrigerant type. Installing an incompatible compressor can lead to performance issues and premature failure.

- Proper Refrigerant Handling: Ensure the refrigerant charge is correct for the specific system. Overcharging or undercharging can significantly impact the compressor’s performance and efficiency. Always follow the manufacturer’s recommendations for the type and amount of refrigerant.

- Secure Mounting: Proper mounting is essential to prevent vibration and noise issues, which can lead to mechanical wear and tear over time. Ensure that the compressor is securely fastened and that all mounting bolts are tightened to the manufacturer’s specifications.

- System Cleanliness: Before installing the new compressor, it’s crucial to ensure that the entire system is clean and free of contaminants. Flushing the system to remove any debris, moisture, or acids can prevent these from causing damage to the remanufactured compressor. Additionally, replacing the filter drier is recommended to maintain system cleanliness.

Maintenance Tips for Longevity of Your Commercial Carrier 06E Compressor

Once the remanufactured Carrier 06E compressor is installed, regular maintenance is key to maximizing its lifespan and ensuring optimal performance. Here are some essential maintenance tips:

- Monitor Oil Levels and Quality: Regularly check the oil level and quality in the compressor. Low oil levels can lead to inadequate lubrication, causing increased wear on internal components. Additionally, contaminated oil can lead to poor performance and potential damage.

- Inspect Electrical Connections: Periodically inspect the electrical connections to ensure they are tight and free of corrosion. Loose or corroded connections can lead to voltage drops, increased heat, and potential motor failure.

- Check for Refrigerant Leaks: Regularly inspect the system for refrigerant leaks, as low refrigerant levels can cause the compressor to overheat and fail prematurely. Utilize leak detection methods such as electronic detectors or ultraviolet dye to identify and address leaks promptly.

- Monitor System Pressures: Keep an eye on the system’s operating pressures to ensure they are within the manufacturer’s recommended range. Abnormal pressures can indicate issues such as restrictions in the refrigerant circuit, improper refrigerant charge, or failing components, all of which can affect compressor performance.

- Conduct Regular Vibration Analysis: Vibration analysis can help detect early signs of mechanical issues within the compressor, such as bearing wear or misalignment. By identifying these problems early, you can take corrective action before they lead to more significant damage.

- Maintain Condenser and Evaporator Coils: Ensure that the condenser and evaporator coils are clean and free of debris. Dirty coils can reduce system efficiency, causing the compressor to work harder and potentially leading to overheating and failure.

Review Your Commercial HVAC/R Compressor Today

Remanufactured Carrier 06E compressors offer a cost-effective and reliable solution for commercial HVAC/R systems when sourced from reputable remanufacturers and installed and maintained properly. By following the best practices outlined in this post, you can maximize the performance and longevity of these compressors, providing your clients with a dependable and efficient cooling solution. As always, staying informed about the latest industry standards and best practices will help you deliver the best possible service to your clients while ensuring the success of your HVAC/R projects.