Performance and efficiency are two of the most crucial considerations when you are buying or replacing a commercial compressor. Performance refers to the unit’s ability to deliver the results it needs. It is about choosing a compressor with the right size and power for the job without unnecessary overhead.

Efficiency, on the other hand, is the ability of any piece of equipment to deliver the required performance at a better price. Efficiency usually refers to a unit’s ability to do its work at a lower level of power consumption than the competition offers. Efficiency can also be measured in terms of service life and reduced repair costs.

There are several different ways to maximize performance, but none is more important than making the right selection of compressor. Once you’ve chosen a compressor, you need to stick with the same make and model for your configuration going forward. That makes replacing a compressor a major turning point.

Luckily, there are ways to use a remanufactured commercial compressor to improve your results.

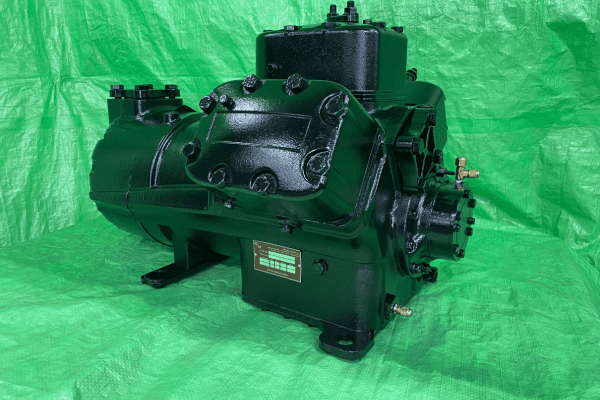

A Remanufactured Commercial Compressor Meets or Exceeds All OEM Standards

A remanufactured commercial compressor is ideal for maximizing performance, especially in commercial air conditioning and refrigeration. In addition to getting the performance and quality you need faster and at a lower cost, you sometimes end up with a commercial compressor that actually exceeds OEM standards.

That’s because a remanufactured commercial compressor undergoes a complete engineering process that is even more detailed than what you might expect from brand-new manufacturing. Every detail is checked, and every function is tested before the unit is sent back to the customer.

With testing being performed at each phase of the build process, you can rest assured that your remanufactured commercial compressor will be at least as good as new, meeting every OEM benchmark and reaching all relevant environmental standards. Occasionally, a remanufactured compressor will even beat those standards.

The Benefits of a Remanufactured Commercial Compressor Are Second to None

A compressor that beats your expectations might seem like enough on its own, but that’s really only the start of the advantages of a remanufactured commercial compressor. Not only do you get easier access to all the best commercial compressor brands, but you also get them faster and at a lower price.

Why Are Remanufactured Compressors Less Expensive than OEM Compressors?

Remanufactured compressors are less expensive than a new compressor from the OEM or the OEM wholesaler for a variety of reasons. One of the biggest is that you don’t have to wait for a new compressor core to be fabricated, which is the most intensive manufacturing process in the creation of any new compressor.

For many models, a quality remanufacturing company has an inventory of the more popular models ready to go into service almost immediately, which reduces or eliminates the wait time normally required when purchasing a new OEM compressor. The sales process involves the customer promptly returning their defective core in exchange for the newly remanufactured compressor. This process saves the customer from paying the core charge that is often built into the price by OEM’s and their affiliated wholesalers.

With a remanufactured commercial compressor, several components are always replaced. For example, o-rings, gaskets and some other parts are always replaced and other components are thoroughly tested and replaced if they don’t meet requirements. Even though this is a comprehensive process, it’s a lot less expensive than manufacturing a new one, and you reap the savings.

Last but not least, there are fewer middlemen involved in the production of a remanufactured commercial compressor. When you order a “new OEM compressor,” you’re usually not getting a 100% new product. Instead, you get a remanufactured compressor from an OEM’s affiliated wholesaler.

While these affiliates do need to maintain certain standards so they remain accredited by the OEM itself, you are effectively paying extra for a brand name without any guarantees that you will actually get the benefits of complete commercial compressor remanufacturing the way you will with a dedicated remanufacturing firm.

For Replacement Compressors and New Setups Alike, Remanufactured Compressors Can’t Be Beat

Most companies will buy a remanufactured commercial compressor for their regular commercial compressor replacement every eight to ten years or so. However, if you are setting up a brand-new facility and maximizing performance and uptime is a key concern, you can use remanufactured compressors as standby units.

Whether you are focused on commercial refrigeration, commercial HVAC applications, or a mix of both, a remanufactured commercial compressor ensures that you have the most control possible over the timing of your compressor replacement. In terms of maximizing performance, maximizing efficiency, and saving both time and money, you simply can’t go wrong with a remanufactured commercial compressor.