Commercial HVAC/R compressor remanufacturing stands at the intersection of sustainability and efficiency, offering a viable solution for extending the lifespan of critical machinery. However, the success of this process hinges on meticulous adherence to stringent quality standards. In this blog, we will discuss the essential quality benchmarks necessary to uphold the reliability and performance of remanufactured compressors.

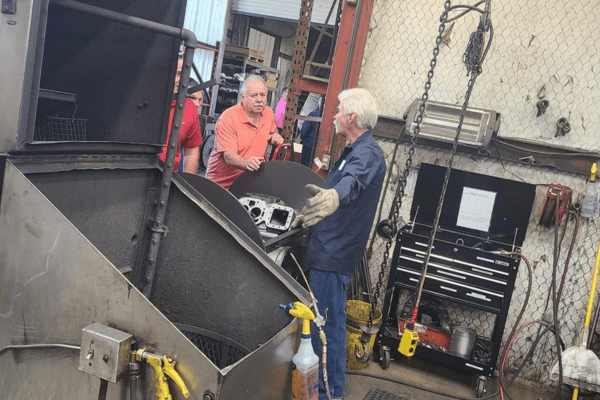

At the core of commercial HVAC/R compressor remanufacturing lies a thorough evaluation of components. This initial phase involves disassembly and inspection, where each part is scrutinized for wear, damage, or deviations from specifications. Precision is paramount, and adherence to recognized standards ensures consistency and accuracy throughout the process.

ASTM Standards For Remanufacturing

Dimensional measurements serve as the backbone of component evaluation. ASTM International standards provide comprehensive guidelines for conducting precise measurements and assessments. These standards ensure that components meet exacting specifications, minimizing the risk of performance issues or premature failures post-remanufacturing.

Non Destructive Testing Techniques For Remanufacturing

Non-destructive testing (NDT) techniques play a pivotal role in identifying defects that may not be visible to the naked eye. Methods such as magnetic particle testing and ultrasonic testing help detect flaws in materials or welds, ensuring the structural integrity of remanufactured components. By adhering to NDT standards, remanufacturers can confidently certify the reliability of their products.

Repair processes must also adhere to established standards to guarantee the integrity of remanufactured components. Welding, for instance, is governed by AWS (American Welding Society) standards, which dictate acceptable practices for joining metals. By following these guidelines, remanufacturers of commercial HVAC/R compressors ensure that welds meet the necessary strength and quality requirements.

Surface treatments, such as coatings or platings, are applied to enhance the durability and performance of components. ASTM standards provide specifications for these treatments, dictating parameters such as thickness, adhesion, and corrosion resistance. Adherence to these standards ensures consistent and reliable outcomes, bolstering the longevity of remanufactured compressors.

Quality Control is a Must for Remanufacturing of Commercial HVAC/R Compressors

Quality control measures are woven into every stage of the remanufacturing process to validate the integrity of components and assemblies. Functional testing simulates real-world operating conditions, ensuring that remanufactured compressors meet or exceed performance expectations. Pressure testing verifies the structural integrity of critical components, safeguarding against leaks or ruptures under operational pressures.

OEM Specifications: Preserving Original Integrity

Original Equipment Manufacturer (OEM) specifications serve as the blueprint for commercial HVAC/R compressor remanufacturing. By adhering strictly to OEM guidelines, remanufacturers ensure the preservation of original design integrity. This entails using replacement parts that meet or exceed OEM specifications, adhering to specified tolerances, and employing approved assembly techniques. By maintaining adherence to OEM specifications, remanufactured compressors not only meet but often exceed the performance and reliability of their original counterparts.

EPA Compliance: Environmental Responsibility

Environmental Protection Agency (EPA) compliance is non-negotiable in commercial HVAC/R compressor remanufacturing. If mishandled, refrigerant gases used in HVAC/R systems can have significant environmental impacts.*Before compressors are shipped to the remanufacture all refrigerant is removed from by the customer. When compressors are sent to the clients, it is only shipped with only a nitrogen charge.

Remanufacturers, like Compressors Unlimited, must adhere strictly to EPA regulations governing the handling, recovery, and disposal of all chemical waste. Additionally, remanufacturers can pursue EPA certifications such as the GreenChill Partnership, demonstrating a commitment to minimizing environmental impact throughout the remanufacturing process.

Elevating Standards, Ensuring Excellence With Remanufactured Commercial HVAC/R Compressors

Continuous improvement is a cornerstone of quality assurance in compressor remanufacturing. By embracing lean manufacturing principles, remanufacturers identify inefficiencies and streamline processes to enhance productivity and quality. Employee training and development programs foster a culture of excellence, empowering staff to uphold the highest standards of craftsmanship and attention to detail.

As the demand for sustainable solutions continues to rise, commercial HVAC/R compressor remanufacturers must elevate their standards, embracing excellence at every stage of the remanufacturing process. By prioritizing quality, adhering to guidelines, and embracing environmental responsibility, remanufacturers can forge a future where reliability, efficiency, and sustainability converge seamlessly in the fascinating world of commercial HVAC/R.