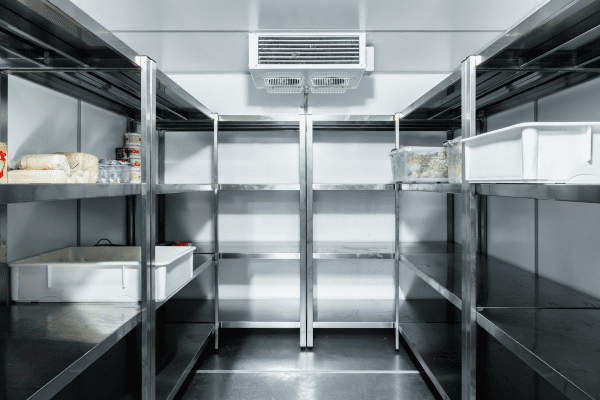

A commercial freezer is one of the most important pieces of equipment you’ll find in the average restaurant. The loss of refrigeration for just a few minutes can mean throwing out thousands of dollars in food. Of course, this is just one of many places where you can find commercial freezers in action, but they are always crucial.

Commercial freezers can be many times larger than residential freezers. As a result, they have bigger, heavy-duty commercial compressors. In some cases, multiple commercial compressors work together to ensure the freezer will always be just as cold as you expect it to be.

For the businesses that use them, commercial freezers are a “workhorse” that can last for years or decades. As with every other major piece of equipment, it’s critical to clean them and perform the right commercial freezer maintenance so you can maximize their service life.

The question is: When should you repair a commercial freezer?

And when is it time to replace a commercial freezer?

When Can You Repair Your Commercial Freezer Unit?

The most vital component of any commercial refrigeration or commercial HVAC system is the compressor. The compressor provides the mechanical energy necessary for the cooling cycle. It makes refrigerant gas available so the rest of the system can function as expected.

A commercial compressor should last at least ten years, with proper maintenance, and it is not out of the ordinary for it to make it to fifteen years or even longer. Most of the time, common problems with your commercial freezer are not related to compressor performance at all. Rather, reduced performance begins with the seal on your freezer door.

If you notice that your commercial freezer doors and hinges have taken a lot of damage or the freezer doesn’t close as tightly as it should, repair is necessary right away. By the time this issue is noticeable, your freezer’s temperature is probably already lower than it should be. Luckily, repairing a commercial freezer door is simple.

As for a commercial freezer’s walls and floors, most incidental damage to the walls won’t reduce cooling ability. Even large marks and dents are usually superficial. But you should be careful to ensure that the floor remains level, even, and intact. A slip and fall inside a commercial freezer can be devastating.

If your commercial freezer isn’t performing the way it should be, commercial freezer repair usually includes the replacement of the evaporator or coils before the compressor itself is touched. A broken fan within the freezer should take only about an hour to replace completely.

When Is It Time to Replace a Commercial Freezer or Commercial Freezer Compressor?

Regular commercial compressor maintenance will give you a better idea of when it’s actually time to replace the unit. While it’s unusual for a commercial compressor to suddenly fail before ten years, not all units will make it to fifteen or twenty years. Age is the major factor that tells you when it is appropriate to replace a compressor.

Another telltale sign is when the cost of commercial freezer repair is going up. If you notice there are more issues and they take a bigger investment from you, the commercial compressor might be at the root of your worries. The compressor can work harder to compensate for other components, but the reverse is not true.

Remember that there are many changes you can make to your walk-in freezer configuration to make it more efficient without having to replace major pieces of equipment. For instance, when there are theft concerns, a new glass door is a quick and cost-effective way to prevent shrinkage.

When It’s Time to Replace a Commercial Freezer Compressor, Use Remanufactured Compressors

A commercial freezer compressor tends to be a cut above the rest in size, power, redundancy, and reliability. With that in mind, you could find yourself paying a premium if you decide to source replacement equipment directly from an OEM or their affiliated wholesaler. Remanufactured compressors are the way to go.

A remanufactured commercial freezer compressor has undergone a complete re-engineering process. Functions are tested and verified before the compressor is returned to the customer. We carry a large compressor inventory and can often ship out a replacement compressor the same, or next day which will minimize your system downtime. If needed, or requested, we can also remanufacture your compressor core and return it to you in a 3-5 business day timeframe.

Remember, almost all “new” compressors you source from an OEM are actually remanufactured. In the long run, you are paying for the brand name only. By comparison, a dedicated compressor remanufacturing team saves you 10%, 20%, 30%, or even more while meeting all of your performance and environmental needs.

When it comes to a commercial freezer or any other large piece of refrigeration equipment, the best way to save time and money is to take action before a mission-critical equipment failure happens. A remanufactured commercial compressor gives you one more valuable option.