When you need reliable cooling or refrigeration, a Carrier commercial compressor is the way to go.

As summer cranks up the heat across the country, more organizations that rely on their commercial compressors are taking a close look at their current units. While it’s not usually possible to swap out a compressor for a new make and model, some leaders are taking the unusual step of rebuilding their entire system.

What’s driving the change? Heat records are getting broken left and right as the world notches eight of the hottest years on record. In some places throughout the South and Southwest, compressors that were once considered “ready for anything” are failing before their time.

And it’s not just the heat, it’s the humidity too!

Humidity is water vapor in the air. In addition to making any temperature “feel” hotter than it is, it exposes your commercial refrigeration or HVAC system to a variety of problems. Metal parts are more vulnerable to corrosion, and your compressor may end up working harder, drawing more power, and potentially failing unexpectedly.

In today’s world, you need a compressor that’s prepared for unprecedented conditions.

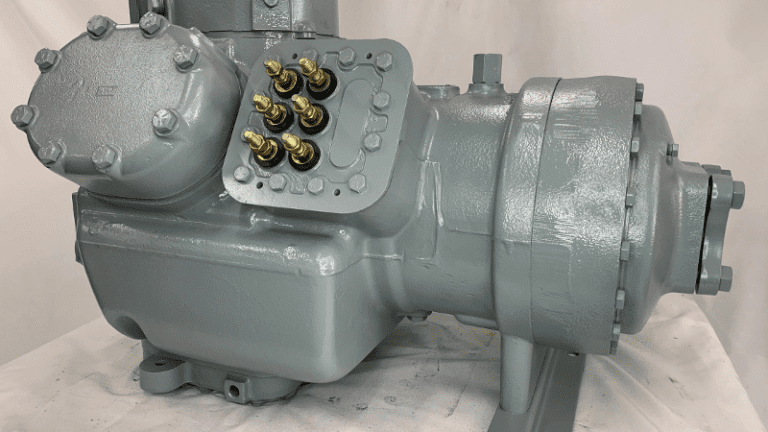

When you want to beat the heat, you need a Carrier 06E commercial compressor.

When the Heat Is On, Turn to the Carrier 06E Compressor for Reliable Performance

You’ve heard of Carrier, but you might not have heard of the Carrier 06E compressor until recently.

The Carrier 06E compressor first became popular in marine condensing units. Marine applications are also in high demand and there’s often no way to make field repairs or pull into port if a compressor fails. Once word caught on among we land lubbers, Carrier 06E compressors were seen more and more in other industries.

Over the last year, it’s been one of the most popular Carrier compressors on the market.

Let’s dive deeper into its details and why it might be the right choice for you:

1. Superior Lubrication

Reciprocating compressors are familiar and easy to use but wear and tear continues to be on many owners’ minds. With an advanced high-flow oil pump, you benefit from automatic reversing and positive displacement lubrication under all operating conditions. That greatly extends the life of your compressor unit.

2. Pressure Equalization

Ensuring pressure equalization is one way to defend your compressor against flooding and slugging, which may destroy an otherwise sound compressor. The Carrier 06E compressor’s crankcase venting system equalizes the pressure during startup, giving rise to better ease of starting and higher energy efficiency overall.

3. Extra Redundancy for Safe Lubrication

The Carrier 06E compressor is equipped with an oversized sump that holds a substantial quantity of extra oil in the crankcase. In the event of a flooded start, this makes it much less likely that the unit will drop below a safe lubrication level.

4. Higher Capacity and Efficiency

While some compressor manufacturers have switched their focus to screw compressors, scroll compressors, or even large centrifugal compressors, Carrier continues to innovate on the reciprocating compressor. This is truly evident in the contoured pistons that lower cylinder clearances, improving all the unit’s key performance metrics.

5. Increased Flow of Refrigerant

Running low on refrigerant is the most common issue for commercial HVAC systems and should always be top of mind if they aren’t working the way they should. Carrier’s highly efficient valve design ensures increased refrigerant flow throughout the system and lower drops in pressure no matter what the operating environment throws at it.

6. Electronic Oil Pressure Switch

An electronic oil pressure switch is much more effective than a traditional mechanical switch. You can look forward to greater accuracy, higher reliability, and faster response to any oil pressure changes. It’s also far easier for electronic switches to trigger an alarm or automatic shutdown if adverse conditions arise.

Get All the Benefits of the Carrier 06E At a Fraction of the Cost

Want to experience all the Carrier 06E compressor has to offer at a price you can be pleased with?

Consider a remanufactured commercial Carrier 06E compressor.

With a remanufactured commercial compressor, you won’t have to sit around waiting for a new compressor core to be fabricated by an OEM or sourced by an OEM-affiliated wholesaler. Your existing compressor core is used, so a replacement can begin right away.

During compressor remanufacturing, the unit is opened and thoroughly cleaned. Each component is checked by expert commercial engineers and all necessary replacements are made. In the end, the compressor is tested, so you know it is ready to go for another eight to ten years.

The result is a unit that meets all your performance and environmental requirements, done faster and at a discount that can exceed 30%. It’s the perfect way to beat the heat!