Sustainability is at the forefront of many businesses’ agendas, and the choice of remanufactured commercial compressors is gaining traction for more than just cost-effectiveness. Beyond the financial advantages, these remanufactured units offer substantial environmental benefits, contributing to waste reduction and resource conservation. Let’s see why opting for remanufactured commercial compressors can be a significant win for both your operations and the planet.

Reducing Waste through Remanufacturing

One of the most significant environmental benefits of choosing remanufactured compressors is the reduction of waste. Typically, when a compressor reaches the end of its service life, it’s disposed of, contributing to the ever-growing pile of electronic waste. However, remanufacturing intervenes in this linear approach by extending the lifespan of these units.

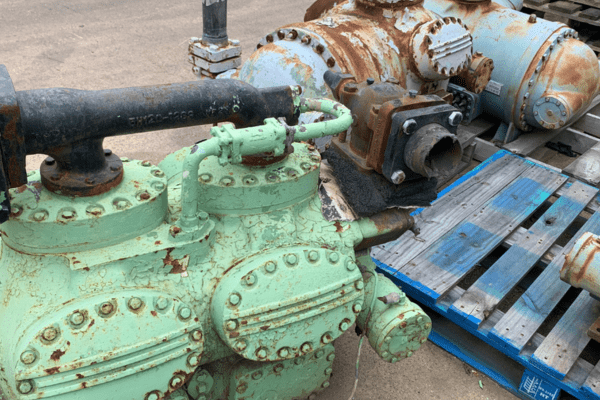

Remanufacturing involves completely disassembling the compressor, thoroughly inspecting each component, and replacing all worn or damaged parts. This process breathes new life into the compressor, essentially giving it a second chance at usefulness. By salvaging and refurbishing these units, remanufacturers divert them from landfills, thus reducing the environmental burden associated with electronic waste disposal.

Conservation of Resources for Commercial Compressors

Apart from waste reduction, remanufactured compressors contribute to conserving valuable resources. Manufacturing new compressors demands significant amounts of raw materials, energy, and water, all of which have environmental implications. By choosing remanufactured commercial compressors, businesses bypass the need for producing cast iron castings for new units, thereby conserving these precious resources.

Remanufacturing typically requires fewer raw materials compared to manufacturing from scratch. Instead of extracting virgin resources, remanufacturers utilize existing components that have been tested and meet or exceed original specifications, minimizing the strain on natural ecosystems. Additionally, the energy and water required for the remanufacturing process are often lower than those needed for new production, further lessening the environmental footprint.

Energy Efficiency and Carbon Footprint Reduction

Beyond waste reduction and resource conservation, remanufactured commercial compressors also offer energy efficiency benefits. Older compressors may not be as energy-efficient as newer models due to wear and tear on components. However, through remanufacturing, these units undergo refurbishment, including the replacement of inefficient parts with more energy-efficient alternatives.

Improved energy efficiency translates to reduced energy consumption during compressor operation. This not only lowers utility bills for businesses but also reduces the carbon footprint associated with energy generation. By opting for remanufactured commercial compressors, companies can actively contribute to mitigating climate change by curbing greenhouse gas emissions.

Promoting Circular Economy Principles for Remanufactured Commercial Compressors

Choosing remanufactured compressors aligns with the principles of the circular economy—a regenerative system aimed at minimizing waste and maximizing resource utilization. In a linear economy, products follow a “take-make-dispose” trajectory, leading to resource depletion and environmental degradation. However, the circular economy seeks to close the loop by extending the lifespan of products through practices like remanufacturing.

By embracing remanufactured commercial compressors, businesses participate in this circular approach, keeping valuable resources in use for as long as possible. This not only reduces the demand for new production but also fosters a more sustainable and resilient economy.

Remanufactured Commercial Compressors Are a Win For Everyone

The environmental benefits of choosing remanufactured commercial compressors extend far beyond cost-effectiveness. These units play a crucial role in waste reduction, resource conservation, energy efficiency, and promoting circular economy principles. By opting for remanufactured commercial compressors produced by a reputable business like Compressors Unlimited, businesses not only save money but also contribute to a healthier planet by minimizing their environmental footprint. As sustainability continues to be a driving force in business decisions, embracing remanufactured compressors represents a step towards a more environmentally conscious future.