Today’s commercial compressors are a lot more reliable than those of the past. Generally speaking, you won’t see a modern commercial compressor fail “out of the blue.” There’s always an underlying reason whenever a compressor suffers a malfunction.

These days, you can count on virtually any compressor for nearly a decade of useful life. There are differences between various makes and models, but they don’t usually amount to a major difference in lifespan. To give a common example, a reciprocating commercial compressor is no longer at a high risk of failure.

While a reciprocating compressor might have more moving parts and experience more wear and tear than a comparable screw compressor, it’s designed to last for 8-10 years with appropriate maintenance. On the other hand, some compressors may retain optimal efficiency longer into their service life.

Let’s take a closer look at the differences and what you can expect from your commercial compressor.

Here’s How Long the Average Commercial Compressor Will Last

It wasn’t that long ago when a commercial compressor would last for eight years, tops. These days, the same commercial compressors are designed to last anywhere from eight to ten years, or longer. This is the gold standard for compressors that receive appropriate maintenance and have the right operating environment.

As a rule, if you have a problem with your commercial HVAC or refrigeration system, the compressor is least likely to be the culprit. In fact, most problems can be easily resolved and are due to simple oversights – things like making sure you’ve got an adequate supply of compatible refrigerant for the unit to use.

Catastrophic failure typically results from infiltration of liquid or debris into the compressor (as seen in cases of flooding and slugging). Electrical defects sometimes lead to sudden failure but are far more likely to do damage over the course of weeks or months. Running the compressor improperly accounts for most other failures.

Even though modern compressors are built to last, that doesn’t mean there are no big differences between them. The better you treat your compressor, the more of its efficiency it’ll retain over the years. That could amount to a savings of thousands of dollars since lower efficiency means more energy use.

It’s also wise to keep an eye on your compressor since it gives you the opportunity to replace it at the right time. Remember that “eight to ten years” is a range. The compressor could last ten years (or even a little bit longer) or it could fail the day after its eighth birthday. That’s why it’s crucial to have a plan in place.

Extending the Life of Your Commercial Compressor

The most important thing you can do to extend the life of any commercial compressor is to make sure it gets the right maintenance. Compressor maintenance is broken down into weekly, monthly, quarterly, and annual tasks.

Many of today’s compressors aren’t built for extensive field repairs beyond the occasional replacement of an O-ring, valve plate or other small part. But that doesn’t mean there’s nothing you can do. Monitoring the compressor itself and the operating environment will pay dividends in the long run.

Have a complete compressor maintenance plan in place and be sure everything is documented. Documentation means nothing can be overlooked, it’s easier to know which compressor spare parts you need more of, and you can notice patterns and get to the root of issues before they become serious.

Whenever possible, use a semi-hermetic commercial compressor. Semi-hermetic compressors are designed so the compressor is completely sealed away from the operating environment but can still be accessed when it’s time for maintenance. This cuts down on a wide variety of hazards.

Newer compressors include on-board electronics that interface with popular building management systems. The additional hardware captures granular data on compressor performance and can let you know about any potential problems when they are still in the earliest stages.

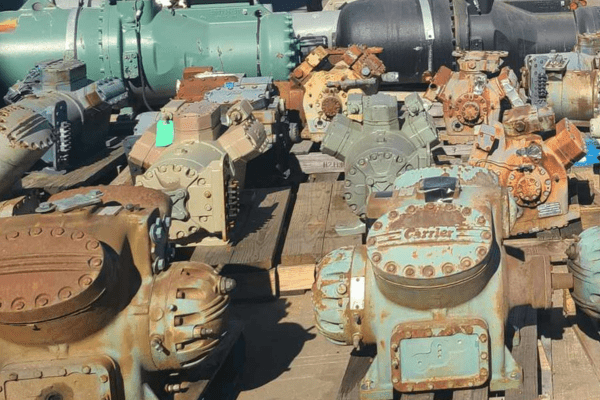

A Remanufactured Compressor Lasts Just as Long as All-New Compressors

Sooner or later, you’ll need to replace your commercial compressor, so always have a plan ready.

The easiest way to replace a commercial compressor is to use a remanufactured commercial compressor. A remanufactured compressor uses an existing compressor core as the foundation of a new system. After complete re-engineering, the remanufactured unit performs identically, if not better, to all-new compressors.

A remanufactured commercial compressor is a sound investment. Like other compressors, it will last eight to ten years. But you also get the advantage of being able to direct all questions to your remanufacturing team throughout the unit’s life. Remanufacturing gets done faster and typically leads to a substantial discount.

All in all, today’s compressors are more reliable than ever before. For best results, always give your compressor the maintenance it needs – and be prepared for replacement when the time is right.