To keep your business moving forward, you know you need your compressor to deliver the best possible performance for as long as it can. Maintenance is a major part of that, no matter what make or model of compressor you use. Design factors can make your compressor maintenance routine easier or harder.

Even with the best intentions, it’s easy to overlook steps in your compressor maintenance plan when it feels like the compressor itself is working against you. For the safety of your personnel and the longevity of your system, convenience is always a good thing.

Your ability to maintain your commercial compressor depends to a great extent on easy access to its parts and systems. Yet, this hasn’t been a top priority for many compressor manufacturers in the past. Luckily, Trane is bucking the trend with a whole new approach that makes your life easier.

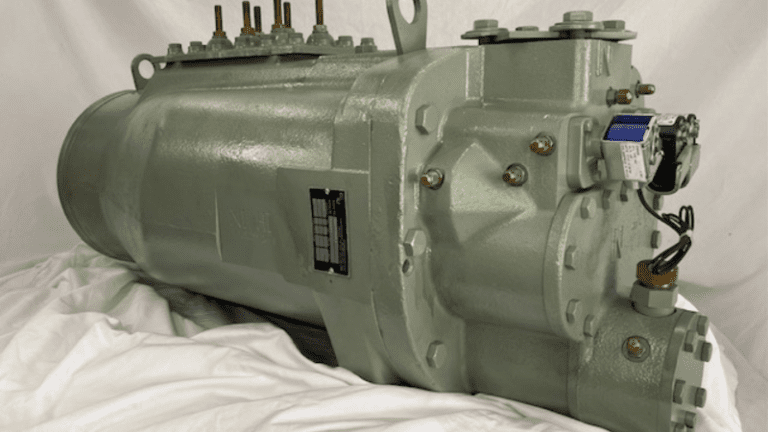

High accessibility is one of the many ways the Trane CHHP compressor is there for you.

Trane CHHP Addresses Some of the Biggest Complaints About Commercial Compressors

The Trane CHHP is a screw compressor with a number of key differences.

When you think of a screw compressor, you probably don’t think of complex field replacements of key components. You might replace an o-ring now and then, for example. But even though the process of keeping the compressor going is streamlined, that doesn’t mean it doesn’t have needs.

Serviceability is a key factor in compressor performance as you aim to get the best output you can from your unit, especially in the second half of its 8-10 year lifespan. Trane heard about the complaints that the average screw compressor attracts and has taken decisive action to change everything.

The Trane CHHP compressor represents a redesign long in the making.

Get Familiar with the Powerful Re-Imagined Features of the Trane CHHP

Let’s consider some of the most valuable upgrades and updates in the Trane CHHP compressor:

1. Convenient Placement of the Loading and Unloading Valves

One of the biggest changes is the location of the loading and unloading valves. This small part may only be a few inches, but it has a critical role. It ensures smooth startup to your compressor and reduces the wear and tear on the motor from startup and shutdown.

The Trane CHHP positions crucial valves right in front of the compressor, so you never struggle to gain access to them. That’s better for your compressor and better for you! You won’t have to bend, pull, twist, and turn to get where you need to go. Instead, you’ll get vital insight into any issues faster.

2. Changing the Oil Filter Is a Breeze

Changing the oil filter is one task you can’t get away from, even with a screw compressor. Trane works to accelerate and simplify the process. Everything you need to execute a filter change is consolidated near the front of the unit, not far from the loading and unloading valves.

The oil return features a dedicated shutoff valve so it can be isolated from the system. This means you’ll be able to switch out the filter in a matter of minutes. Even the “crankcase” heater is located just beside the oil access cover. You’ll end up saving hours every single year, thanks to these little adjustments.

3. A Roomy and Technician-Friendly Terminal Box

The more room in your terminal box, the easier it is to see at a glance what you need to do and keep things organized. Wiring the unit is a fast and painless process with the Trane CHHP compressor. You have ample room to make connections – far more than most competing compressors can offer.

The Trane CHHP Compressor Is a Natural Fit for Commercial Compressor Remanufacturing

Ease of access, sound construction, and strong performance make the Trane screw compressor one of the most durable and dependable. With the power of a remanufactured commercial compressor, you’ll never be caught without the equipment you need when it finally comes time to replace a compressor.

Working with thousands of Trane compressors over the years, we’ve noticed time and time again that their compressor cores tend to be in reliable shape. The compressor core is the heart of the unit and essential to the remanufacturing process. With it, there’s no need to fabricate an all-new core.

This dramatically reduces both the expense and the wait associated with getting a compressor that performs like new in every way. Quality, power usage, and environmental impact are tested to verify they are exactly what you would expect if you purchased an all-new compressor.

The lesson is clear: Be good to your Trane CHHP screw compressor and it will be good to you. With its ease of access and a bevy of features to support compressor maintenance crews, the CHHP makes that simpler than ever.