Buyers want to be sure that when they invest in a remanufactured commercial compressor, they are getting their money’s worth. A remanufactured commercial compressor can be sourced weeks sooner than a unit a wholesaler has to offer, typically at a discount of 10%, 20%, or even more. But where does it come from?

No matter whether you’re using a reciprocating compressor, a screw compressor, or some other kind of compressor, you will need a compressor core for remanufacturing. At Compressors Unlimited, we are transparent about our compressor cores. You know what you’re getting every time.

Many of our remanufacturing projects start with a compressor core provided directly by the customer. The core comes from the old unit and is the basis of all the work we do. However, we also maintain our own inventory of compressor cores. These come from reliable sources fully vetted by our team of experts.

Customers Like You Benefit from Our Access to the Compressor Core Exchange

The compressor core exchange process is the main source of compressor cores for remanufacturing.

Virtually every compressor manufacturer has established a compressor core exchange that helps keep a wide variety of compressor cores in circulation. It benefits compressor manufacturers to keep these cores out of a landfill because every remanufactured compressor is one they don’t need to fabricate from scratch. Many of the compressors no longer can be manufactured 100% new simply because the cast body is not available.

Likewise, customers like you benefit because the cost of getting the same or better than new compressors into service is kept lower for everybody. That’s more important now than ever because a remanufactured commercial compressor cuts out thousands of miles of your supply chain. There are fewer delays and mistakes to deal with.

When you purchase a remanufactured compressor from Compressors Unlimited, you’ll notice there’s a line item for a core charge. This is separate from the line item charge for your new compressor, the associated taxes, the shipping, and so on. This charge is assessed upfront, then credited back after you receive your old compressor core back. Some OEM’s and other remanufacturers may build the core charge into the purchase price and others may choose to hold the core charge invoice until 10 days or more after the compressor purchase in hopes that you can return the core in that short timeframe.

Your technician will send us your previous compressor core and the money will be returned or a credit will be issued to your account. As mentioned in the previous paragraph, there are some compressor manufacturers who don’t break down their invoices with these line items, but regardless, you are always paying a core charge.

Sourcing Compressor Cores from Indirect Lines

With our years of experience, we have some unusual ways of getting high-quality compressor cores from makes and models that are more difficult to come by. We have developed a worldwide network of trusted contractors that maintain their own stockpile of compressor cores. These cores are stored safely when they leave service – then, when it’s time to remanufacture a commercial compressor, they are sold to us in batches.

Every compressor core that comes through Compressors Unlimited has been carefully inspected by our team and often by our other contacts throughout the industry. The majority of these compressor cores come from situations where a full HVAC replacement was warranted for reasons unrelated to compressor performance.

We Use Only Compressor Cores That Can Meet 100% of Performance and Environmental Commitments

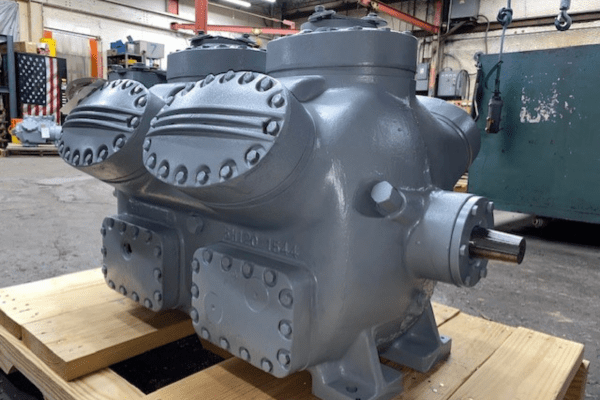

The ultimate goal of compressor remanufacturing is to ensure you get equipment that is comparable in all ways to a new unit sourced from an OEM wholesaler. After remanufacturing, the final product meets all performance and environmental commitments and is ready to be used for eight to ten more years of service.

There is no room for less than the best when it comes to true compressor remanufacturing. We don’t simply swap out worn parts, but carefully test all functions. Incoming compressor cores need to already be in fairly good condition in order to meet these high standards once everything is said and done.

Our expertise means we know when a compressor core simply won’t hack it.

Our quality control standards ensure every compressor is tested rigorously as the remanufacturing process unfolds. Each one receives more than a dozen tests covering every function and verifying components are functioning optimally. In the end, the unit is tested under load – that is, “simulated real-world conditions.”

In effect, the remanufactured commercial compressor is shown to function under conditions that match your workplace so you can rest assured you get value from the first day it arrives at your facility. This is completely different from some organizations that claim to “recondition” or “renew” compressors, but only clean them.

When you’re in the market for a new commercial HVAC compressor, it’s wise to shop around. Compare all the costs, including the core charge, before you make a decision. You’re always welcome to contact us directly, or you can have your HVAC technician work with our team to sort out the details for your approval.

At Compressors Unlimited, we believe in the value of remanufacturing commercial compressors – and our process means you’ll enjoy that value to the fullest.