When you’re dealing with a piece of equipment like a commercial compressor, the decision to repair or replace is a big one. Cost is the major factor that weighs on your options. At the same time, taking the right action to minimize business disruption is also crucial.

There are several things to take into consideration.

1. How Serviceable Is Your Compressor?

The general trend in compressor technology is toward ease of maintenance. Still, that doesn’t mean your problem is easily solved. Some of the most sophisticated commercial compressors out there today really aren’t built for field repairs, so replacement becomes the obvious route.

You might have had a screw compressor for years and do little more than replace an o-ring.

If the compressor can’t be serviced effectively, or it’s only possible to make a temporary fix, you need to start considering your options for replacement. In many cases, the fastest way to realize an emergency replacement is through a remanufactured commercial compressor using your existing compressor core.

2. How Old Is Your Compressor?

Commercial compressors are built to last, and they’ve even extended their service lives over the last decade or so. Having a commercial compressor run for up to 10 years is commonplace. Still, it’s also normal to see some level of efficiency loss in the latter half of that time span.

You can combat efficiency loss through a structured maintenance plan and having the right compressor spare parts on hand. But it’s also wise to take a total systems view of your building. If you’re seeing the cost of cooling or refrigeration climb, your compressor is showing its age – even if it’s still functional.

If your compressor is five years or older, you should start planning for replacement. However, it’s often possible to get excellent results from a compressor up until the very end of its life. Review the costs of your unit’s operation to decide. Also, verify whether repairs have become more frequent or costly.

That way, you can make a sound judgment about whether replacement is worthwhile.

3. Has the Compressor Had a Critical Failure?

When the operating environment is set up according to the compressor’s parameters, early failure of the compressor itself is extremely rare. Failure is most likely to be brought on by system problems, human errors or oversight. The most likely culprit is a problem elsewhere in the building’s system that interacts with the compressor.

If a compressor fails “out of the blue” and no maintenance has been missed, it’s important to look at the surrounding circumstances. Electrical problems or issues like flooding and slugging are likely to be at the heart of the matter. Root cause analysis ensures the next compressor won’t meet the same fate.

Most of the time, critical failure means you need to replace a commercial compressor completely. It may be possible to repair it, but the damage is often so widespread it isn’t advisable. If the compressor core is damaged, starting over with another unit will put you on an even footing for the future.

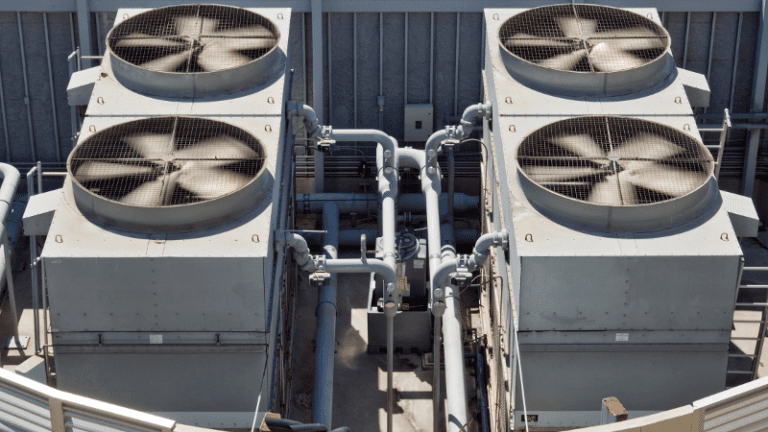

4. What’s the Status of the Rest of Your HVAC or Cooling System?

When there are inefficiencies elsewhere in your setup, your compressor will naturally work harder to compensate. Most of the time, it’s the only part of an HVAC or cooling equipment that puts mechanical force into the system. Like the human heart, it’s constantly pumping.

In this case, what’s recirculating all that time is refrigerant. The first thing to check in any failure is that you have sufficient refrigerant and it isn’t leaking. From there, you can look for other aspects that may be the cause of your dilemma, starting with any components that haven’t seen maintenance lately.

Once in a while, you’ll discover that unwanted behavior from a commercial compressor is actually the fault of some other upstream problem. This can usually be handled with the right compressor spare parts and could be resolved in just an hour.

The Rule of Thumb for Repairing or Replacing a Compressor

When a commercial compressor is young, always try to extend its service life with repairs.

When the compressor is showing its age, carefully consider the costs and benefits of replacement.

No matter when you decide to replace, a remanufactured commercial compressor is the fastest and least expensive way to do it. With remanufacturing, you get a unit that can meet all of your commitments with “like new” performance and environmental standards.

A remanufactured commercial compressor is typically 10%, 20%, or even 30% less expensive than one you source from an OEM-affiliated wholesaler. Since your existing compressor core is the basis of the work performed, it can also be done in a fraction of the time.

While repair is often cheapest, a well-timed replacement has the biggest impact. Make an informed choice, but don’t wait too long!