Typically, if you are buying a compressor for replacement purposes, your strategy is simple.

You need the same model from the same brand as the unit you’re replacing. It’s that easy.

In some cases, though, you’ll find yourself comparing many different makes and models to come to a final decision. This is typical in situations where you’re doing a full design and build of a new system. In cases like that, it’s a good idea to work from the top down until you arrive at the specific compressor you need.

The Compressor Model You Were Using May No Longer Be Available

Sometimes a replacement compressor will differ from the existing one because the original model is no longer available. If that appears to be the case, be sure to check in with a commercial compressor remanufacturer. A good remanufacturer may have an inventory of legacy models ready to perform at their best for 8-10 years.

You May Need a Compressor that Meets a Higher Environmental Standard

Over the last few years, stricter environmental regulations have played a role in decisions about compressor replacement. With new commercial refrigerant rules in place, no one wants to be the last organization around that’s relying on an ever-dwindling supply of a highly expensive refrigerant that will soon be obsolete.

Let’s say that you’ve determined you need a York commercial HVAC compressor.

You have already done a lot of the work, but you are not quite done yet.

Let’s review some of the top considerations to keep in mind when choosing your compressor model.

Start with Your Application Requirements and Work from There

Taking a close look at your needs will help you narrow down the field of York compressors considerably.

1. Light Duty or Heavy Duty?

Partial load operation can make a compressor much more efficient than it would otherwise be, as it does not have to run at full horsepower when its workload is dwindling. This is great when you know the compressor will need to work to full capacity at least some of the time, but do not expect it to happen all of the time.

If you anticipate your compressor will be on light duty much of the time, you could save money on deployment by choosing a single-stage compressor instead. A single-stage compressor runs at full power whenever it is powered on, so it is crucial to size the compressor carefully in relation to its operating conditions.

2. Which Refrigerant?

Lots of modern compressors have been designed with the capability to use multiple refrigerant types. That helps you save money and differentiates from older models. Regulations permitting, select a model that allows you to safely use up your existing reserve of refrigrant and then switch to a widely available alternative.

Understanding York HVAC Compressor Models

Although all compressors perform the same basic functions, there are many ways to implement the technology. The principal work of the compressor is to pressurize the refrigerant gas, making it available to the rest of the system. The compressor will tend to work harder and draw more energy as other system components wear out.

On the other hand, when the compressor fails, the rest of the system grinds to a halt!

With appropriate maintenance, a commercial HVAC compressor will operate from 8-10 years. The major goals of new compressor technology are to make compressors more serviceable and enable them to perform at their best for longer into their service life. This partly explains the diversity in York compressor technology.

York is well-known for excellence in its centrifugal compressors, screw compressors, and scroll compressors.

Centrifugal Commercial Compressors

Centrifugal compressors have a tendency to be the largest of the bunch and are designed for the most heavy duty applications. As the name suggests, they compress refrigerant vapor through centrifugal force, which typically requires a major draw of power. Hospitals, universities, and large marine vessels use them.

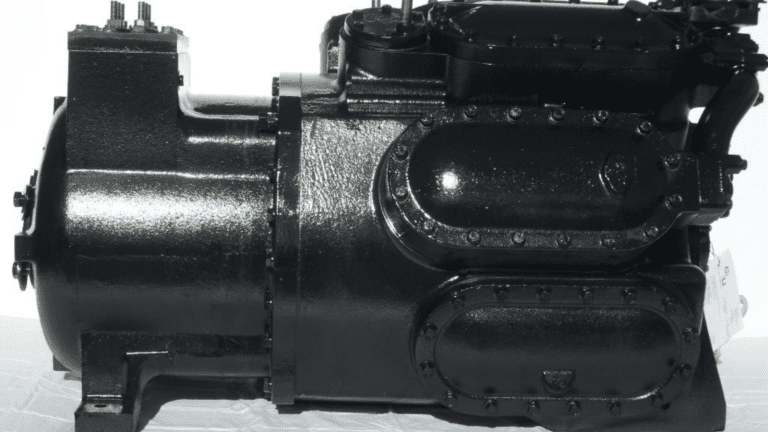

Screw Compressors

Commercial screw compressors are also known as rotary compressors. These move refrigerant from low to high pressure areas using rotors (“screws”) that trap refrigerant gas in a compressor casing. York screw compressors are optimized for medium-load cooling projects and facilities with mission critical low temperature demands.

Scroll Compressors

York scroll compressors provide continuous compression of the refrigerant through the action of one orbiting and one fixed scroll. They can be used in a wide range of projects. Since they are available in many sizes, it is especially important to carefully size the compressor to the application so you can avoid waste.

If you aren’t sure which compressor is best for you, get advice from a team of experienced experts. Depending on your needs, you may also be able to benefit from a remanufactured commercial compressor. This allows you to enjoy the benefits of York quality at a significant savings.