Of all the commercial enterprises that rely on precision refrigeration, distilleries have some of the most precise standards. Distillery chillers must maintain precise temperatures throughout all the stages of the process. If any issues arise, the taste will be off or the entire batch could be ruined.

The principal function of the distillery chiller is to remove the excess heat that arises during fermentation and distillation. Temperature controls may be fine-tuned down to half a degree or even less. This helps ensure that consistent, high-quality spirits are the end result, no matter which specific type of product you are making.

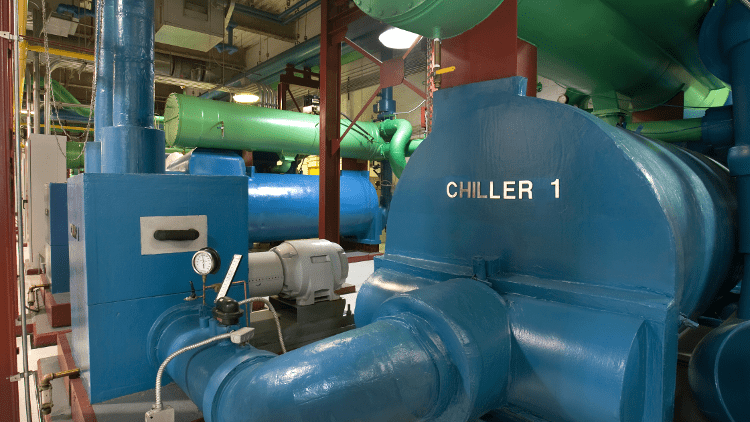

Distillery Chillers May Work Even Harder than Standard Commercial Refrigeration Systems

A distillery may have multiple different chillers that work together to create the right production environment. During the fermentation stage, temperature controls are necessary to convert sugars into alcohol efficiently. If temperatures are not held within a tight tolerance, unwanted and potentially dangerous byproducts can result.

Distillation makes a difference between premium spirits and those that are not nearly as valuable to consumers. Distillation helps separate the pure alcohol from the other components of the process, creating a more refined product. This enables you to get a more potent and distinctive result than you would have otherwise.

Distillery chillers often run 12+ hours a day. Not only do they run near peak capacity when fermentation and distillation are underway, but they are also involved in storage. For the best flavor, top-shelf spirits must stay chilled all throughout the journey from the distillery to the retail location!

Distillery Chillers Use a Variety of Technologies, But One Element Stays the Same

Distilleries may use a variety of different approaches – air-cooled, water-cooled, and glycol-cooled systems can all be found. Of these, glycol-cooled systems are typically the most demanding. They rely on food-grade propylene glycol, a sophisticated, highly controlled chemical that can safely come into contact with food products.

Unlike common commercial refrigerants, propylene glycol functions as a heat transfer fluid in secondary cooling systems. These systems usually consist of three main components: A chiller, a precise glycol-water mix, and heat exchangers or cooling coils. In these systems, the compressor is part of the chiller unit itself.

The industrial compressor is directly integrated into the chiller unit, which has the function of cooling the glycol and water mixture before circulating it. In that sense, the compressor plays a similar role to the one you are used to from other cooling and refrigeration applications. As in other industries, compressors must be maintained regularly.

Distillery Chilling Systems Face Unique Challenges

Distillery chiller systems must be designed carefully because they usually have large instantaneous cooling loads coupled with a defined period of operation. A smaller chiller can be used when the production environment has been properly optimized to make use of the downtime required by many distillery processes.

Ultimately, this can lead to a smaller and more efficient chiller.

Several different components come together to deliver distilled spirits, including the mash cooker, still, cold water vessel, re-circulation skid, and the glycol cooler itself. While all these are crucial, the cooler is the most complex. It can be difficult to repair and costly to replace, especially if the compressor breaks down.

Distillery teams need specialized knowledge to maintain their equipment. As a result, maintenance is often done by professionals who have broad insight into the alcohol distillation process. Even so, it’s just as vital to understand the engineering principles involved and how they affect the final product.

Even when your goal is to create award-winning spirits, be attentive to your industrial compressor.

A Remanufactured Industrial Compressor Protects Your Distillery’s Bottom Line

Without a compressor, your distillery will be “on ice” until you can source a replacement. Since 2020, it has taken longer and longer to get the equipment you need from an OEM-affiliated wholesaler. But there is an alternative that works for businesses like yours: A remanufactured industrial compressor.

With a remanufactured industrial compressor, your new unit uses your current compressor core. This means you don’t have to wait for an all-new core to be fabricated – and that’s much better for the environment, too.

With the thorough engineering process of a proven remanufacturing team, you get a unit that’s ready to serve all your needs for another eight to ten years. Your remanufactured compressor meets all the performance and efficiency standards of the original, helping you keep your productivity high and commitments intact.

From the production floor to the highest levels of leadership, distillery professionals find remanufactured commercial compressors give them the reliable performance they want. That boosts your bottom line by protecting you from unexpected compressor failures and reducing the cost of compressor maintenance.

Next time you need a compressor at the best prices, raise a glass to a remanufactured industrial compressor.