The compressor is one of the more expensive components to replace in a commercial HVAC system. However, the systems are built dynamically and will serve you for many years without breaking down, if you follow the appropriate maintenance procedures.

When compressors break down and can’t be repaired, you need to replace them. The timing is often inconvenient not only for the time of year but for your budget as well. This is one of the many reasons remanufactured compressors are chosen.

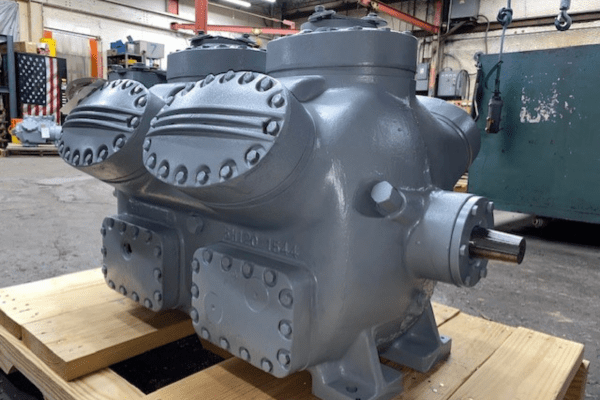

Overview of Remanufactured Compressors

Due to the high cost of manufacturing compressors, remanufactured units are a popular replacement option for commercial installations.

A remanufactured compressor is an existing unit that has been overhauled and tested to function as well as a brand-new OEM compressor. When a used compressor is remanufactured, all of the replaceable and worn-out parts are replaced. Among the critical components that are replaced in a typical semi-hermetic or screw/helirotor compressor include:

- Bearings & inserts

- All Gaskets

- O-Rings, seals & valves

- Valve Plates

- Crankshaft

- Motor and rotor

A remanufactured compressor provides the same level of performance as a new unit and has the same lifespan. For the compressor to be made available to a customer, it must meet or exceed the performance and reliability standards of a new OEM unit. All Compressors Unlimited remanufactured compressors come with a comprehensive limited warranty that covers all factory defects.

Did you know that many OEMs prefer to sell remanufactured compressors rather than new ones? Most compressor units sold in the US and around the world are remanufactured either by an independent remanufacturing company or by OEMs themselves.

Why Choose a Remanufactured Compressor

Here are some of the reasons why many commercial HVAC experts recommend going for remanufactured compressors over new ones:

1. Cost Savings

You can save up to 60% by replacing an old compressor with a remanufactured unit rather than a new compressor. How?

Old compressor styles can be expensive to maintain and may not perform optimally. On the other hand, 100% new compressors are costly and may require extensive installation changes during changeovers.

This leaves remanufactured compressors as a viable replacement option for your industrial cooling and refrigeration systems. These compressors should be of the same model as the units that have to be replaced.

2. Easy Maintenance Due to Familiarity

Unless you are doing a fresh HVAC installation, you are better off with a remanufactured compressor that your team is familiar with. The HVAC technicians will have an easier time installing and maintaining the unit.

3. Easy Access to Parts

When you are working with a reputable compressor remanufacturing company, you can be sure that you are getting quality replacement parts. In fact, the business model of remanufacturing companies is based on having a large amount of parts available for the most popular compressor models. With this as the case, you will often find easier access to replacement parts for your compressor than you would when dealing with an OEM.

You can also order a bespoke compressor remanufacture that suits your current needs. You can ask the remanufacture to replace parts with specific parts and even do some alterations, such as tandem bracketing or enclosures, to fit your current or desired setup.

Other Considerations of New Vs. Remanufactured Compressors

Environmental Impact

Reusing industrial compressors contributes to environmental sustainability efforts while saving costs. Environmental sustainability principles are reduction, reusing, and recycling, otherwise known as the three Rs of waste management. Several studies, including one published in the Journal of Remanufacturing comparing remanufactured against new compressors, confirmed the positive impact of using remanufactured units in commercial HVAC systems on the environment.

Reusing industrial compressors means less heavy industrial materials are sent to the landfills. At the same time, fewer natural resources are used towards the manufacture of OEM compressors, thus reducing overall carbon emissions.

Choosing a Remanufactured Compressor

The most popular remanufactured compressor brands include Carrier Carlyle, Bitzer, Copeland, Trane and York. Which brand do you use in your facility?

When looking for a remanufactured compressor, you should match the compressor brand and model number to the one you are replacing. Installing such a remanufactured compressor will be easier, and you won’t require many changes to the current setup.

Other things to keep in mind include the warranty that is provided with the remanufactured compressor, and whether the remanufacturing company offers other benefits such as 24/7 technical support.

Purchasing a remanufactured compressor is a wise move, whichever way you look at it. The units have a lower up-front cost but still give the same levels of performance as their new counterparts.