When your Carrier compressor starts acting up, you are ultimately faced with the decision to repair or replace. Deciding how to spend your money is a big deal, and the toughest question is assessing the value of repairing your compressor against the long-term benefit of replacing it altogether. HVAC compressor failure can be detrimental to your business. Here are a few tips to help you get a better idea of which method will serve your needs when it comes to compressor repair.

Factors that Affect Cost

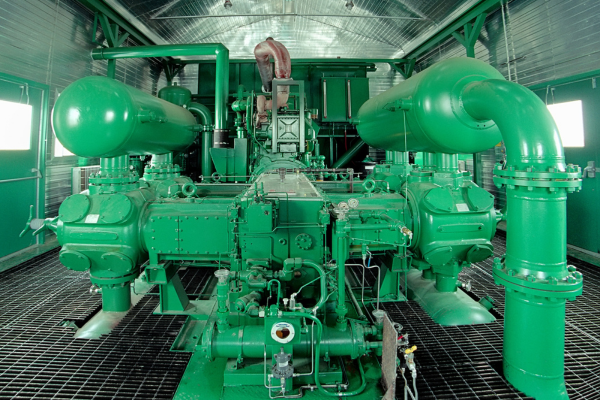

Before you can estimate the cost of repairing or replacing your Carrier compressor, you first need to know exactly why it is not working properly. All compressors are complex systems that do include wearable parts. Some of these parts are easily swapped out and the unit is sent back to work right away. Other parts are not meant to be wearable and once they go out, there is no simple fix. Thus, the first thing you need to do is have your compressor inspected to see exactly where the point of failure is. This inspection should also reveal if there is other damage within the system that will soon lead to larger problems.

You also need to consider whether or not your compressor is still covered by any kind of warranty. In some cases, the cost of repair or replacement may be completely canceled out by a manufacturer warranty.

Finally, the age of your compressor will surely affect whether or not it is reasonable to make a repair. If your entire compressor is well-aged, you may find that replacement parts are hard to come by, or that the manufacturer no longer supports your compressor model. Your technician may also advise that ordering a replacement part could take weeks or months. If you do not have time to wait for the replacement of an old part, it may be time to replace your compressor altogether.

When to Repair

If your HVAC technician is confident that the worn part can be easily fixed, and that the age of the compressor itself will not be a factor in trying to locate parts, then repairing your compressor may be the best choice for you. In addition, if the cost of the repair is well under 50% of the total replacement cost of the unit, you are probably safe. However, if the replacement part and labor for the repair are more than 50% of the replacement cost, you probably just want to go ahead and replace the compressor. Otherwise, your next repair will push you over the cost of a replaced unit and you will have lost money.

What to Consider When Replacing

While replacing your Carrier compressor may cost more in the short term, it may not be quite as expensive as you expect. Once your remanufactured compressor is installed, you will see a reduction in your energy costs month to month. In fact, if your old compressor had been operating below its peak efficiency because the internal parts were wearing down, you may see more savings than you expect. You will definitely want to compare your monthly operating expenses to see just how much of a savings you are earning.

Before you jump to any conclusions about the state of your Carrier compressor, it is best to consult an expert who can help explain the type of damage your system has sustained and the possible solutions to your problem. They will be able to give you a better idea of the costs associated with either path. Just make sure you ask plenty of questions and fully understand what future costs may be associated with a repair or replacement of your Carrier compressor. Visit Compressors Unlimited today to see a full selection of Carrier products as well.